Experiencing a Volvo Link hardware failure can be frustrating. This issue disrupts your vehicle’s connectivity and performance.

Understanding the root cause and solutions is essential. Volvo Link hardware plays a crucial role in maintaining the vehicle’s connectivity. When this hardware fails, it can lead to numerous issues, from navigation problems to disrupted communication features. Addressing these failures promptly is vital for ensuring your car runs smoothly and safely.

In this blog, we will explore the common causes of Volvo Link hardware failures, their impact on your vehicle, and practical solutions. By understanding these aspects, you can take informed steps to maintain your Volvo’s performance and connectivity. Stay tuned to learn more about diagnosing and fixing these hardware issues.

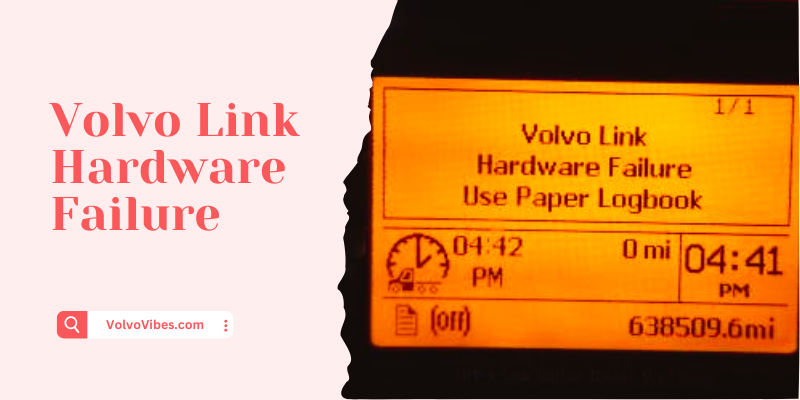

Credit: www.pinterest.com

Introduction To Volvo Link Hardware

Volvo Link Hardware failure can disrupt vehicle communication systems. This issue affects data transfer and vehicle diagnostics. Quick resolution is essential to maintain vehicle performance.

Volvo Link Hardware forms a key part of Volvo’s telematics system. This technology connects vehicles with a central system. It helps in monitoring and managing fleet performance. Volvo Link Hardware enhances vehicle efficiency. It allows for real-time tracking and diagnostics. This technology ensures a smoother and more controlled operation.Purpose And Importance

The main purpose of Volvo Link Hardware is communication. It transmits data between the vehicle and central system. This data provides insights into vehicle health and performance. Efficient data transmission reduces downtime. It also helps in predictive maintenance. Early problem detection leads to quick repairs. This prevents costly breakdowns and enhances fleet reliability. Volvo Link Hardware also supports driver safety. Real-time alerts notify about potential issues. This enables timely corrective actions.Common Issues

Despite its benefits, Volvo Link Hardware can face issues. One common problem is hardware failure. This can disrupt data transmission. Power supply problems can cause hardware failures. Loose connections or damaged cables can interrupt performance. Software glitches can also affect functionality. Regular updates and maintenance can prevent some of these issues. Environmental factors like extreme temperatures can impact hardware. Proper insulation and protection can mitigate this risk. “`

Credit: volvovibes.com

Identifying Hardware Failure

Volvo Link hardware failure can disrupt vehicle communication and diagnostics. Identifying the issue early helps prevent serious damage and costly repairs. Regular checks and timely maintenance ensure smooth operations.

Experiencing a hardware failure in your Volvo Link can be frustrating. Understanding the signs and symptoms helps you address issues quickly. Early detection can save time and prevent further damage. Let’s explore how to identify hardware failure effectively.Signs And Symptoms

Watch out for common signs of hardware failure. One of the first signs is erratic behavior of the device. You might notice the screen freezing or flickering. Another symptom is unresponsive controls. If the buttons stop working, it is a red flag. Pay attention to unexpected shutdowns. If the device turns off randomly, it needs attention. Slow performance is also a clue. If the system lags, it might be failing.Diagnostic Tools

Use diagnostic tools to confirm hardware issues. Volvo provides specific software for this purpose. Connect your device to a computer. Run the diagnostic software. The tool will scan for problems. It will generate a report detailing any issues. This helps pinpoint the exact problem. Use this information to decide the next steps. Sometimes, a simple reset can fix minor issues. For major problems, professional assistance is required. “`Common Causes Of Failure

Volvo Link hardware is crucial for vehicle communication and diagnostics. Understanding the common causes of failure can help in preventing unexpected breakdowns. This section explores these causes in detail.

Environmental Factors

Environmental factors can significantly impact Volvo Link hardware. Exposure to extreme temperatures is a major cause. Both high heat and freezing cold can damage the hardware components. Additionally, moisture and humidity can lead to corrosion. This can impair the functionality of the hardware.

Another environmental factor is dust and dirt. These can infiltrate the hardware, causing blockages and malfunctions. Ensuring a clean environment for the hardware can mitigate these risks.

Wear And Tear

Wear and tear is inevitable over time. Regular use leads to physical degradation of the hardware. This includes the wearing out of connectors and cables. Repeated plugging and unplugging can weaken connections.

Moreover, the internal components also suffer from wear. This can lead to reduced performance and eventual failure. Routine maintenance and timely replacements can help manage wear and tear.

| Cause | Impact |

|---|---|

| Extreme Temperatures | Damage to hardware components |

| Moisture and Humidity | Corrosion |

| Dust and Dirt | Blockages and malfunctions |

| Wear and Tear | Physical degradation |

Initial Troubleshooting Steps

Experiencing Volvo Link hardware failure can be frustrating. Understanding the initial troubleshooting steps can help you diagnose and fix the issue. Follow these steps to get started.

Basic Checks

- Ensure all cables are securely connected.

- Check if the power supply is stable.

- Verify that the device is turned on.

- Inspect the hardware for any visible damage.

- Test with another power outlet to rule out electrical issues.

Reset Procedures

Sometimes, a simple reset can solve many problems. Follow these reset procedures:

- Unplug the device from the power source.

- Wait for 30 seconds to ensure a complete discharge.

- Plug the device back in and turn it on.

- If the issue persists, perform a factory reset by holding the reset button for 10 seconds.

Ensure to back up any important data before doing a factory reset.

Advanced Diagnostic Techniques

Experiencing Volvo Link hardware failure can be frustrating. Knowing how to diagnose the issue is crucial. Advanced diagnostic techniques help pinpoint the problem. This guide covers software tools and hardware testing methods.

Software Tools

Using software tools is the first step in diagnosing Volvo Link hardware issues. These tools can perform various functions:

- Error Code Retrieval: Software can read error codes from the vehicle’s system.

- System Scans: Comprehensive scans identify faults.

- Data Logging: Track and log data for detailed analysis.

One popular tool is the Volvo Tech Tool (VTT). It helps in identifying specific issues. It also offers solutions and repair instructions.

Another useful tool is VIDA (Vehicle Information and Diagnostics for Aftersales). VIDA provides detailed diagnostics, software downloads, and updates. It is essential for accurate troubleshooting.

Hardware Testing

After software diagnostics, hardware testing is the next step. This ensures all physical components are functioning well. Here are some methods:

- Visual Inspection: Check for visible damage on cables and connectors.

- Continuity Testing: Use a multimeter to check for electrical continuity.

- Voltage Testing: Ensure components receive the correct voltage.

Testing the ECU (Engine Control Unit) is vital. A faulty ECU can cause numerous issues. Use an oscilloscope to check signal integrity.

Another key component is the Telematics Control Unit. Testing this unit involves checking signal strength and connectivity.

Regular maintenance and testing can prevent many hardware failures. Keeping your diagnostic tools updated is also essential. This ensures accurate readings and effective problem-solving.

Repair And Replacement Options

Experiencing a Volvo Link Hardware Failure can be frustrating. Knowing your repair and replacement options can make the process easier. Below, we explore different approaches to get your Volvo back in top shape.

Diy Repairs

If you are handy with tools, DIY repairs can be a good option. Here are some steps you can follow:

- Diagnose the Issue: Use a diagnostic tool to identify the problem.

- Order Replacement Parts: Ensure you get genuine Volvo parts.

- Follow the Manual: Consult the vehicle’s manual for repair instructions.

- Test the Repair: Check if the issue is resolved after the repair.

DIY repairs can save money. But they require time and some mechanical skill.

Professional Services

If you are not confident in DIY repairs, professional services are a reliable alternative. Consider the following:

- Certified Technicians: Volvo-certified technicians have the expertise to handle complex repairs.

- Quality Assurance: Professional services offer warranties on repairs and parts.

- Convenience: Most services provide quick turnaround times.

Choosing a professional service ensures your vehicle is repaired correctly. It also saves you time and effort.

Preventative Maintenance Tips

Maintaining your Volvo Link hardware is crucial to prevent failures. Regular maintenance can save time, money, and ensure your vehicle operates smoothly. Below are some preventative maintenance tips that can help you keep your Volvo Link hardware in top condition.

Regular Inspections

Schedule regular inspections for your Volvo Link hardware. Look for signs of wear and tear. Check for loose connections and damaged wires. Ensure all components are secure and functioning properly.

Use a checklist during inspections. This helps you stay organized. Document any issues you find. Address them promptly to avoid major problems later.

Best Practices

Follow the manufacturer’s guidelines for maintenance. Use the recommended tools and parts. Avoid using non-approved components, as they can cause damage.

Keep the hardware clean. Dust and debris can affect performance. Use a soft, dry cloth to clean the components. Avoid using water or harsh chemicals.

Update the software regularly. Software updates often include important fixes. They can improve the overall performance of your Volvo Link hardware.

Credit: www.obd2tool.com

Case Studies And Real-world Examples

Examining real-world instances helps understand Volvo Link hardware failures. Case studies and examples show how these issues impact businesses and what solutions work. Let’s delve into some success stories and lessons learned from these experiences.

Success Stories

One logistics company faced frequent hardware failures with their Volvo Link. This disrupted their operations. The company’s tech team decided to partner with Volvo’s support. They received timely assistance and quick replacements for faulty hardware. Operations soon returned to normal, and they experienced fewer downtimes.

Another example involves a fleet management company. Their trucks’ communication systems failed often, causing delays. They set up regular hardware checks and trained drivers to spot issues early. This proactive approach reduced failures significantly. The company saved both time and money.

Lessons Learned

Hardware failures can cause major setbacks. One crucial lesson is the importance of regular maintenance. Companies that schedule checks and updates face fewer issues. Another lesson is investing in training. When staff know how to identify and report problems, solutions come faster.

Having a good support system is also key. Partnering with Volvo’s support teams can make a big difference. Quick responses and replacements prevent long downtimes. These real-world examples highlight the need for proactive measures and strong support partnerships.

Conclusion And Future Outlook

The issue of Volvo Link hardware failure affects many vehicle owners. This problem can cause stress and inconvenience. However, understanding the solutions and advancements can help.

Summary Of Solutions

There are several ways to address Volvo Link hardware failure. These solutions can help reduce downtime and improve vehicle performance.

| Solution | Description |

|---|---|

| Regular Software Updates | Keep software up-to-date to avoid compatibility issues. |

| Professional Diagnostics | Get expert help to identify and fix hardware problems. |

| Hardware Replacement | Replace faulty hardware with new, reliable parts. |

Regular software updates ensure that your system runs smoothly. Professional diagnostics can quickly identify any issues. If necessary, hardware replacement is a viable option.

Technological Advancements

Technology is always evolving. New advancements can prevent hardware failures and improve vehicle performance.

- Enhanced Connectivity: Better connection reduces the risk of disconnections.

- Improved Hardware Quality: New materials make hardware more durable.

- Advanced Diagnostics: Modern tools quickly identify and solve issues.

Enhanced connectivity means fewer connection issues. Improved hardware quality ensures longer-lasting parts. Advanced diagnostics make it easier to find and fix problems quickly.

In summary, addressing Volvo Link hardware failure involves using current solutions and embracing new technologies. This approach ensures a better driving experience and fewer disruptions.

Frequently Asked Questions

What Is A Volvo Link Hardware Failure?

A Volvo Link hardware failure occurs when the electronic components in the system malfunction or stop working properly.

How Do I Identify Volvo Link Hardware Issues?

Common signs include error messages, malfunctioning displays, or unresponsive controls. Frequent system resets may also indicate problems.

Can A Volvo Link Hardware Failure Be Fixed?

Yes, a certified Volvo technician can diagnose and repair the issue. Sometimes, replacing faulty components is necessary.

How Long Does Volvo Link Hardware Repair Take?

The repair time varies based on the issue. Generally, it can take from a few hours to a day.

Is Volvo Link Hardware Failure Covered Under Warranty?

Yes, if your vehicle is still under warranty. Always check with your Volvo dealer for specific warranty details.

Conclusion

Resolving Volvo Link hardware failures requires timely action and expert help. Regular maintenance can prevent many issues. Keep your system updated to avoid complications. Trust certified technicians for repairs. This ensures safety and reliability. Stay informed about common problems. Early detection saves time and money.

Your vehicle deserves the best care. Don’t ignore warning signs. Address them promptly. By doing so, you maintain performance and peace of mind.