If you’re looking to improve your vehicle’s suspension and handling, understanding why you should use offset ball joints is key. These small but powerful components can make a big difference in how your wheels align and respond on the road.

Whether you’re upgrading your truck or fixing alignment issues, offset ball joints offer benefits that go beyond the basics. You’ll discover how they work, why they matter for your ride, and what to consider before making the switch. Keep reading to find out how offset ball joints can help you get the most out of your vehicle’s performance and safety.

Offset Ball Joint Basics

Offset ball joints are a special type of joint used in vehicle suspensions and steering systems. They help improve alignment and handling. Understanding their basics helps you see why they matter in automotive design.

These joints are designed to adjust the position of suspension components. This adjustment changes the angles of steering and suspension parts. The result is better control and less wear on tires.

Design And Function

Offset ball joints have a unique design that shifts the ball stud away from its usual centerline. This shift changes the geometry of the suspension system. It allows for more clearance between parts like control arms and springs.

The design helps prevent parts from rubbing against each other during movement. It also improves suspension travel and keeps the vehicle stable on rough roads. Offset ball joints support a smoother and safer driving experience.

Tapered Ball Joints Explained

Tapered ball joints have a cone-shaped stud that fits into a matching socket. This shape helps distribute loads evenly. It reduces stress on the joint and increases durability.

The taper ensures a tight fit that resists loosening over time. This feature is important for maintaining proper alignment. Tapered ball joints work well with offset designs to enhance suspension performance.

Performance Benefits

Offset ball joints offer key performance benefits for your vehicle. They improve how suspension and steering work together. These upgrades enhance driving comfort and control. Below are some important performance advantages of offset ball joints.

Improved Suspension Travel

Offset ball joints increase the space between control arms and bump stops. This extra room allows the suspension to move more freely. It helps absorb bumps better on rough roads. The result is a smoother and more comfortable ride.

Enhanced Steering Precision

Using offset ball joints adjusts the position of the steering spindle. This change makes steering more accurate and responsive. Drivers can feel better control over the vehicle’s direction. It reduces wandering and improves handling on sharp turns.

Lift Effect On Vehicle Frame

Offset ball joints push the wheel downward slightly. This movement raises the vehicle frame by the spacer’s thickness. It creates a mild lift without changing the torsion bars much. This lift helps improve ground clearance for off-road driving.

Durability Advantages

Offset ball joints offer notable durability advantages that enhance vehicle performance and longevity. These components reduce stress on suspension parts and minimize damage over time. The design improves the overall strength of the joint, making it last longer under tough conditions.

Using offset ball joints helps maintain the vehicle’s stability and reduces the need for frequent repairs. Their construction supports better alignment and less wear on connected parts. This section explores key durability benefits, focusing on how these joints protect the system from damage.

Reduced Component Wear

Offset ball joints lower the friction between moving parts. This reduction means less heat and wear during operation. Components like control arms and bushings stay in better condition longer. The joint’s offset design spreads forces more evenly.

By minimizing direct impacts, these joints prevent early failure. This leads to fewer replacements and lower maintenance costs. Vehicles equipped with offset ball joints experience smoother rides and improved handling. The durability boost also extends the life of suspension systems.

Prevention Of Interference Issues

Offset ball joints help avoid parts rubbing or hitting each other. Interference can cause damage and reduce part lifespan. The offset design creates space between critical suspension components.

This extra clearance stops metal-to-metal contact that wears parts down quickly. It also prevents stress cracks and bending. The result is a more reliable suspension setup that resists damage from rough driving conditions. Prevention of interference keeps the vehicle safer and operating smoothly longer.

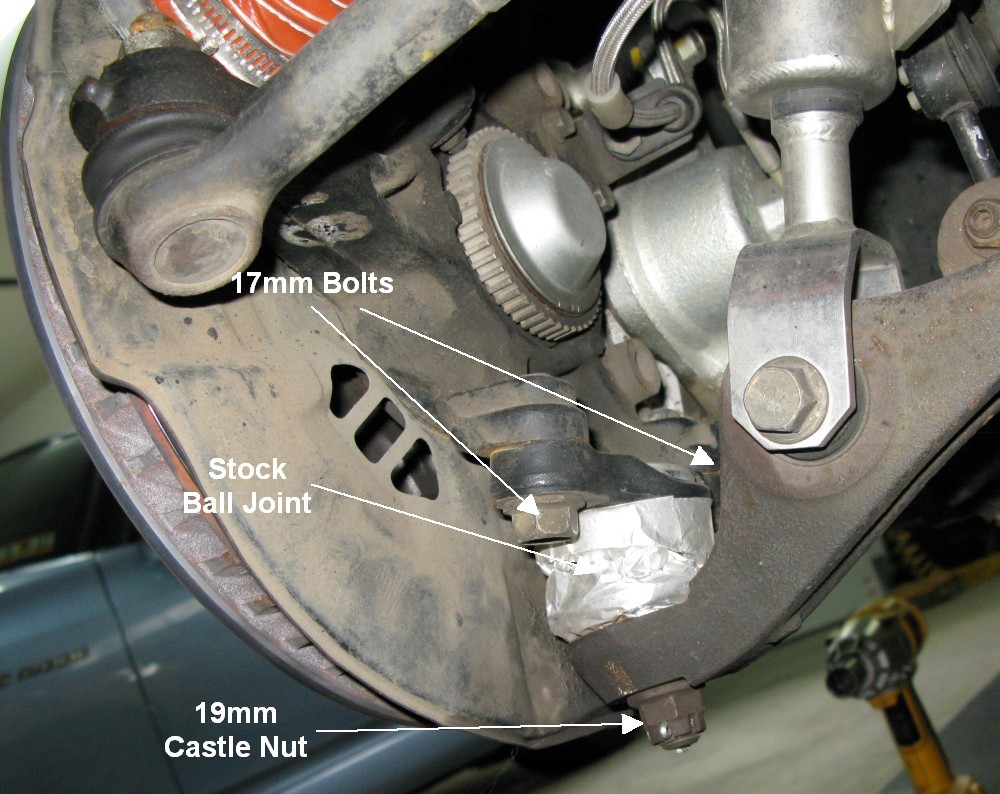

Credit: robrobinette.com

Installation Considerations

Installing offset ball joints requires careful attention to several key factors. Correct installation ensures vehicle safety and optimal performance. Small mistakes can cause poor handling or premature wear. Understanding the main considerations helps achieve the best results.

Proper Placement And Fit

Offset ball joints must fit the vehicle’s control arm precisely. Incorrect placement can lead to uneven stress and failure. Always check the part number and compare it to the manufacturer’s specifications. Use correct tools to avoid damaging the joint or surrounding parts. Proper fit ensures smooth movement and longer joint life.

Importance Of Wheel Alignment

Wheel alignment is critical after installing offset ball joints. The new position changes suspension geometry. Without alignment, tires may wear unevenly and handling will suffer. A professional alignment restores correct angles for camber, caster, and toe. This step improves safety, steering response, and tire life.

Quality And Hardware Selection

Choose high-quality ball joints and hardware for durability and safety. Cheap parts can fail under stress, risking accidents. Use all supplied nuts, bolts, and washers. Replace old or worn hardware to ensure a secure fit. Quality materials resist corrosion and wear better over time.

Common Applications

Offset ball joints have many uses across different vehicle types. They improve suspension geometry and provide better clearance. These joints help maintain steering angles after lifting a vehicle. Many drivers choose them for enhanced performance and safety. Below are some common applications where offset ball joints are essential.

Off-road Vehicles

Off-road vehicles face rough terrain and large obstacles. Offset ball joints allow more suspension travel and better wheel articulation. They reduce stress on the suspension parts during extreme movements. This helps prevent damage and improves vehicle control on uneven ground. Off-road enthusiasts benefit from smoother rides and better handling.

Lifted Trucks

Lifted trucks have higher ground clearance for better off-road capability. Standard ball joints may cause steering and suspension issues after a lift. Offset ball joints correct these angles and keep the suspension working properly. They also reduce wear on tires and other components. Lifted trucks stay safer and more stable with offset ball joints installed.

Jeep Modifications

Jeeps are popular for customization and off-road use. Many Jeep owners install lift kits to improve performance. Offset ball joints help maintain proper steering geometry after lifting. They prevent binding and improve suspension travel. Jeeps with these joints can tackle tough trails with better control and less risk of damage.

Comparing Offset Vs Standard Ball Joints

Comparing offset ball joints with standard ball joints reveals key differences in design and function. Standard ball joints sit directly in line with the suspension arm. Offset ball joints shift the joint slightly to a new position. This small change affects vehicle suspension and steering performance.

Understanding these differences helps in choosing the right ball joint for your vehicle. Each type suits different suspension setups and driving needs. The choice impacts handling, alignment, and overall ride quality.

When To Choose Offset

Choose offset ball joints for lifted or modified suspensions. They work well when the suspension geometry changes. Offset joints adjust the position of the wheel and control arm. This adjustment corrects angles that become misaligned after a lift. They help maintain proper suspension travel and reduce wear on components.

Standard ball joints fit best on stock or slightly modified vehicles. They keep suspension parts aligned as designed by the manufacturer. Using offset joints on a non-modified vehicle may cause poor handling or uneven tire wear.

Impact On Camber And Alignment

Offset ball joints affect camber and wheel alignment directly. Moving the ball joint changes the angle of the wheel relative to the road. This shift helps correct camber issues caused by suspension lifts. Proper camber improves tire contact and vehicle stability.

Standard ball joints maintain factory alignment settings. They keep camber angles within original specifications. Using offset joints requires a professional alignment after installation. This step ensures the wheels track correctly and prevents premature tire wear.

Top Brands And Products

Choosing the right offset ball joint matters for your vehicle’s performance and safety. The best brands offer products that last long and fit well. Quality parts reduce wear and improve suspension lift. Here are some top brands trusted by many drivers and mechanics.

Moog Upper Ball Joints

Moog is known for durable and reliable ball joints. Their upper ball joints provide excellent fit and strength. They use high-quality materials to withstand tough driving conditions. Moog products often include grease fittings for easy maintenance. Many users report smooth steering and less noise after installation.

Mevotech And Delphi Options

Mevotech offers budget-friendly ball joints without sacrificing quality. Their designs focus on corrosion resistance and long service life. Delphi provides premium ball joints with precise engineering. Both brands meet or exceed factory specifications. Choosing Mevotech or Delphi ensures a good balance of price and performance.

Credit: stillen.com

Credit: www.summitracing.com

Frequently Asked Questions

What Are Offset Joints?

Offset joints occur when pipe ends misalign, causing leaks and pressure loss due to friction at the connection points.

What Do Balljoint Spacers Do?

Ball joint spacers raise the vehicle’s frame by increasing space between the upper control arm and ball joint. They provide suspension lift without adjusting torsion bar preload. This improves suspension travel and reduces interference between components, enhancing ride quality and handling after proper wheel alignment.

Why Are Ball Joints Tapered?

Ball joints are tapered to create a tight, secure fit that prevents loosening and ensures smooth rotation within the suspension system.

Who Makes The Most Reliable Ball Joints?

Moog, Mevotech, Delphi, and Transit Warehouse produce the most reliable ball joints known for durability and performance.

What Are Offset Ball Joints Used For?

Offset ball joints help adjust wheel alignment and improve suspension fitment in lifted vehicles.

Conclusion

Offset ball joints improve vehicle suspension and steering performance. They create better alignment and reduce wear on parts. These joints help maintain a smooth ride and increase suspension travel. Installing them can prevent interference in suspension components. Proper installation and alignment are important for best results.

Choosing quality offset ball joints ensures durability and safety. Overall, they offer practical benefits for vehicle handling and comfort. Consider them for a more reliable and efficient suspension system.