When it comes to protecting your vehicle or metal project from rust, choosing the right product can be confusing. You might have heard about Rust Bullet and POR-15, two popular rust-preventive coatings that promise lasting protection.

But which one fits your needs better? Whether you’re dealing with heavy rust or just want to keep your metal looking clean and strong, understanding the key differences between Rust Bullet and POR-15 can save you time and money. You’ll discover how each product works, what makes them unique, and what you should consider before making your choice.

Keep reading to find out which rust solution will give your project the best armor against corrosion.

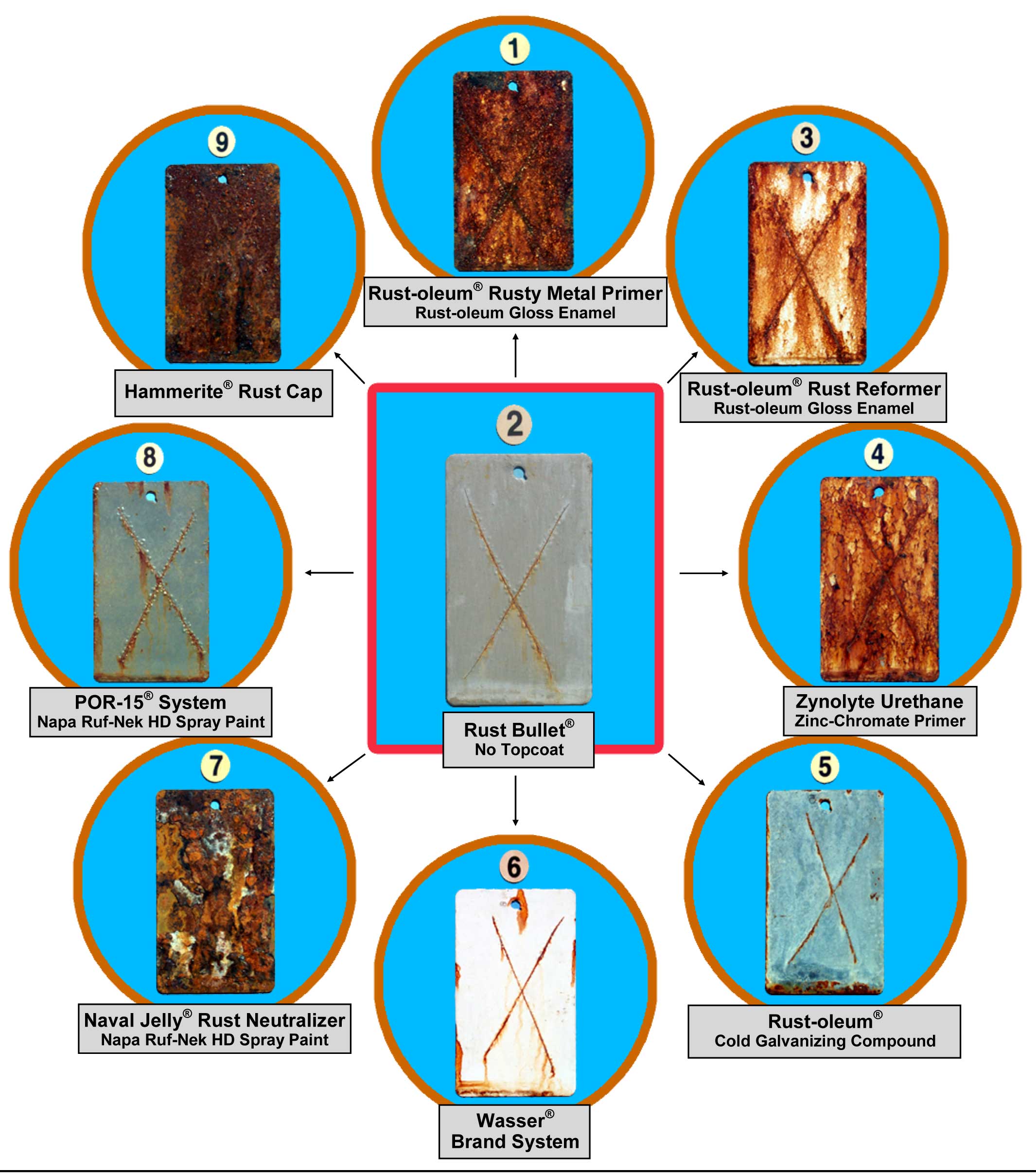

Credit: www.rustbullet.com

Rust Bullet Features

Rust Bullet offers unique features that make it a popular choice for rust treatment. It acts as a rust encapsulator, sealing and protecting surfaces from further corrosion. The product combines rust conversion and coating, creating a strong barrier against moisture and damage. Understanding its key features can help you decide if it fits your project needs.

Adhesion And Flexibility

Rust Bullet sticks firmly to both rusty and clean metal surfaces. Its strong adhesion prevents peeling and flaking over time. The coating remains flexible after drying. This flexibility allows it to handle metal expansion and contraction without cracking. It works well on parts exposed to vibration or movement.

Penetration And Rust Solidification

The product penetrates deep into rusted areas. It chemically solidifies rust, turning it into a stable, hard layer. This stops rust from spreading beneath the coating. The solidified rust forms a protective base for the topcoat. This process extends the life of metal surfaces treated with Rust Bullet.

Uv Resistance And Environmental Impact

Rust Bullet resists damage from sunlight and UV rays. It does not easily degrade when exposed to outdoor conditions. The coating maintains its protective qualities for years. The product is water-based and low in harmful chemicals. It offers a safer choice for users and the environment.

Application Tips

Clean the surface thoroughly before applying Rust Bullet. Remove loose rust, dirt, and grease for best results. Apply at temperatures above 50°F (10°C) and avoid high humidity. Use a brush, roller, or spray for even coverage. Allow the coating to dry fully before adding a topcoat or handling the surface.

Por 15 Features

POR 15 is a popular rust prevention coating used in automotive and metal restoration. It offers strong protection by sealing rust and stopping it from spreading. Understanding its features helps in choosing the right product for your project.

This section explains the key characteristics of POR 15, focusing on how it bonds, what surface preparation it needs, its sensitivity to UV light, and the challenges faced during application.

Chemical Bonding And Coating

POR 15 chemically bonds to rusted metal surfaces. It creates a hard, non-porous coating that stops moisture from reaching the metal. This bonding prevents further rust growth. The coating is tough and resists chipping and cracking under stress.

Surface Preparation Needs

Surface preparation is critical for POR 15’s success. The metal must be free of loose rust, grease, and dirt. Lightly sanding or wire brushing the surface helps the coating stick better. POR 15 does not work well on thick, flaky rust or oily surfaces.

Uv Sensitivity And Topcoat Requirement

POR 15 is sensitive to ultraviolet (UV) light. Direct sunlight causes the coating to fade and degrade over time. Applying a UV-resistant topcoat is necessary to protect the finish. This topcoat also improves the appearance and durability of the coating.

Application Challenges

Applying POR 15 requires careful attention. The coating is thick and can be difficult to spread evenly. It dries slowly, which may attract dust or debris. Temperature and humidity affect drying time and adhesion. Proper ventilation is needed during use.

Performance Comparison

Comparing Rust Bullet and Por 15 reveals important differences in performance. Each product offers unique features for rust protection and metal coating. Understanding these differences helps you choose the right product for your needs.

The following sections break down key performance areas, including rust penetration, durability, flexibility, and peeling resistance.

Rust Penetration Vs Surface Coating

Rust Bullet penetrates rust deeply, sealing and stopping further corrosion. It works well on surfaces with existing rust without full removal.

Por 15 creates a hard surface coating that blocks oxygen and moisture. It requires thorough cleaning and prep for best results on bare metal.

Durability And Chip Resistance

Por 15 forms a very hard, chip-resistant layer after curing. It protects against harsh impacts and road debris effectively.

Rust Bullet is more flexible but still resists chipping under moderate impact. Its durability suits areas with slight movement or vibration.

Flexibility And Crack Prevention

Rust Bullet stays flexible after drying, preventing cracks on bending surfaces. It adapts well to metal expansion and contraction.

Por 15 is rigid and may crack if the metal flexes too much. Best on solid, non-moving parts to avoid cracking.

Peeling And Longevity

Por 15 adheres strongly to clean metal and lasts for many years. Peeling is rare when surface prep is done correctly.

Rust Bullet also lasts long but can peel if rust was not fully removed first. Proper cleaning improves adhesion and prevents peeling.

Credit: www.youtube.com

Surface Preparation Tips

Proper surface preparation is key to getting the best results with Rust Bullet or Por 15. Both products need a clean, well-prepared surface to protect metal effectively. Poor preparation can reduce the coating’s adhesion and durability.

Understanding how to prepare metal surfaces helps you choose the right steps for your project. This section covers tips for handling rusted metal, cleaning, and how preparation affects product performance.

Handling Heavily Rusted Metal

Remove loose rust with a wire brush or sanding tool. Rust Bullet can work on some rust, but heavy rust should be reduced first. Use a grinder or rust remover for deep pits. Por 15 needs metal free of loose rust to stick well. Cleaning rust away improves the coating’s bond and protection.

Clean Metal Preparation

Clean the metal with degreaser or soap and water. Remove oil, dirt, and grease completely. Dry the surface thoroughly before applying either Rust Bullet or Por 15. Avoid touching the metal after cleaning to keep it free of oils. A clean surface ensures better adhesion and longer protection.

Impact On Product Effectiveness

Rust Bullet can handle some rust but works best on properly prepped metal. Por 15 requires a clean, rust-free surface for maximum strength. Poor preparation leads to peeling and reduced protection. Proper surface prep increases coating life and prevents future rust.

Aesthetic Considerations

Choosing between Rust Bullet and POR 15 involves more than just protection. Aesthetic factors play a big role in how your project looks after application. Both products differ in texture, finish, and how they handle topcoats and UV exposure. These details affect the final appearance and durability of your work.

Texture And Finish

Rust Bullet has a thicker, brush-on texture that often leaves a slightly rough surface. This texture can hide minor surface flaws but may not suit smooth finishes. POR 15 offers a smoother finish with a glossy look after drying. It creates a hard, glass-like surface that some users prefer for a cleaner appearance.

Topcoat Compatibility

Applying a topcoat over Rust Bullet is common to improve appearance and durability. It bonds well with most paints, but surface preparation is key. POR 15 requires a suitable topcoat to protect its glossy finish from chipping. Both products accept many automotive topcoats, but check compatibility before applying.

Uv Protection Effects

Rust Bullet contains UV inhibitors that help prevent color fading and cracking over time. This keeps the finish looking better for longer outdoors. POR 15 can yellow or chalk when exposed to sunlight without a protective topcoat. Using a UV-resistant topcoat on POR 15 is essential for maintaining its look outdoors.

Environmental And Safety Factors

Choosing the right rust treatment product involves more than just performance. Environmental and safety factors play a key role. These factors help protect your health and the planet. Rust Bullet and POR 15 differ in these areas. Understanding their impact can guide your decision.

Voc Emissions

Volatile Organic Compounds (VOCs) cause air pollution. They can harm your health and environment. Rust Bullet has moderate VOC levels. POR 15 also contains VOCs but tends to be higher. Lower VOC products reduce harmful fumes. This makes Rust Bullet a better choice for indoor use or confined spaces.

Heavy Metal Content

Some rust treatments contain heavy metals. These metals can pollute soil and water. Rust Bullet has minimal heavy metals. POR 15 contains small amounts of heavy metals like lead and chromium. These metals require careful disposal. Using products with fewer heavy metals helps reduce environmental risk.

User Safety Precautions

Both products need careful handling. Wear gloves and a mask to avoid skin contact and inhalation. Work in a well-ventilated area to reduce exposure to fumes. Avoid eating or drinking while applying rust treatments. Clean tools and wash hands after use. Following safety steps protects your health during application.

Choosing The Right Product

Choosing the right rust treatment product is key to a successful metal restoration. Different situations call for different solutions. Rust Bullet and POR 15 serve similar purposes but excel in different conditions. Understanding your specific needs helps you pick the best product.

Consider the state of your metal, where you will apply the product, and the finish you want. This approach ensures long-lasting protection and a quality look.

Rust Severity And Metal Condition

Assess how bad the rust is before picking a product. Rust Bullet works well on heavily rusted surfaces. It can penetrate and stop rust from spreading. POR 15 is best for clean or lightly rusted metal. It forms a hard, protective coating. For very pitted metal, Rust Bullet may offer better protection.

Application Environment

Think about where you will apply the rust treatment. Rust Bullet is versatile and can be used on frames, underbodies, and other rough areas. POR 15 requires a dry, clean surface to bond properly. It suits indoor or sheltered environments. Temperature and humidity also affect how these products cure and perform.

Desired Finish And Durability

Decide how you want the final look to be. POR 15 creates a smooth, hard finish that resists chipping. Rust Bullet leaves a textured surface but offers flexibility, reducing cracking. Both products provide strong protection, but POR 15 is preferred for a sleek appearance. Rust Bullet is good for areas needing toughness and impact resistance.

Maintenance And Removal

Maintenance and removal play a vital role in the effectiveness of rust protection coatings. Proper upkeep ensures the coating lasts longer and continues to protect metal surfaces. Understanding how to maintain and remove these coatings helps users maximize their benefits and avoid damage.

Longevity And Wear

Rust Bullet offers strong adhesion and flexibility, resisting chips and cracks. It performs well on rusted and bare metal surfaces. POR 15 creates a hard, durable shell that resists abrasion and chemicals. Both coatings can last years if applied correctly and maintained properly. Environmental factors like moisture and temperature affect their lifespan. Regular inspection helps catch any wear early.

Removal Techniques

Rust Bullet is tough to remove because it bonds tightly with the metal. Mechanical methods like sanding or grinding work best for removal. POR 15 also adheres strongly and is difficult to strip off. Chemical paint strippers designed for epoxy coatings can help remove POR 15. Always use safety gear and follow instructions during removal. Proper removal is necessary before reapplying any coating.

Reapplication Guidelines

Before reapplying Rust Bullet or POR 15, remove loose or damaged coating completely. Clean the surface thoroughly to remove dirt, grease, and rust. Light sanding may improve adhesion for the new layer. Both products require dry surfaces before application. Follow manufacturer’s drying and curing times for best results. Reapplication extends protection and maintains surface integrity.

Credit: www.rustbullet.com

Frequently Asked Questions

Which Is Better, Rust Bullet Or Por 15?

Rust Bullet penetrates and solidifies rust into a protective coating, offering flexibility and UV resistance. POR-15 bonds chemically but needs strict prep and lacks UV resistance. Rust Bullet suits rough rust; POR-15 works best on clean metal for a hard, non-peeling finish.

Is Rust Bullet Any Good?

Rust Bullet effectively penetrates and seals rust, providing strong, flexible protection. It requires thorough surface prep and suits heavily rusted metal well. Some formulas resist UV and need no topcoat. Users appreciate its durability, but texture may need covering for a smooth finish.

What’s Better Than Por15?

Rust Bullet often outperforms POR15 by penetrating rust and offering flexible, chip-resistant protection. It requires less prep and resists UV damage better.

Does Por15 Actually Stop Rust?

POR15 chemically bonds to rust, creating a hard, non-porous coating that stops rust from spreading. Proper surface prep is essential for best results. It resists chipping but lacks UV resistance, so it may chalk when exposed to sunlight.

What Is The Main Difference Between Rust Bullet And Por 15?

Rust Bullet is flexible and good for rusted surfaces; POR 15 is harder and best on clean metal.

Conclusion

Choosing between Rust Bullet and POR 15 depends on your project needs. Rust Bullet works well on rusty surfaces and offers good flexibility. POR 15 shines on clean metal and creates a hard, protective coat. Both need proper surface prep for best results.

Consider rust level, desired finish, and ease of use. Either can protect your metal from future rust damage. Think about what suits your skills and project type. This helps you pick the right rust prevention product.