If you’re driving a Peterbilt and notice your fuel tanks aren’t equalizing, you’re not alone—and it can be a real headache. When fuel only flows from one tank or the levels stay uneven, it’s more than just an inconvenience.

It can lead to running out of fuel unexpectedly, costly repairs, and downtime that disrupts your schedule. But why does this happen, and what can you do to fix it? You’ll discover the common causes behind Peterbilt fuel tanks not equalizing and practical steps to solve the problem.

Keep reading to protect your truck’s performance and keep your journey on the road without surprises.

Peterbilt Fuel Tank Systems

Peterbilt trucks use dual fuel tanks to extend driving range. Both tanks must work together to supply fuel evenly. This system avoids running out of fuel on long trips. Two main setups control fuel flow: balance pipes and switching valves. Each has a unique way to manage fuel levels.

Understanding these systems helps diagnose issues like fuel tanks not equalizing. It also guides proper maintenance and repair. Below are details on how each system functions.

Balance Pipe Setup

The balance pipe setup is common in older Peterbilt models. It uses a pipe that connects the two tanks at the bottom. This pipe allows fuel to flow freely between tanks. Fuel moves until both tanks have the same level. Drivers fill one tank, and fuel naturally balances out.

This system is simple and has no moving parts. It relies on gravity and pressure to equalize fuel. Problems occur if the balance pipe clogs or leaks. Blockages stop fuel flow, causing one tank to empty faster. Regular checks keep the pipe clean and free.

Switching Valve Mechanism

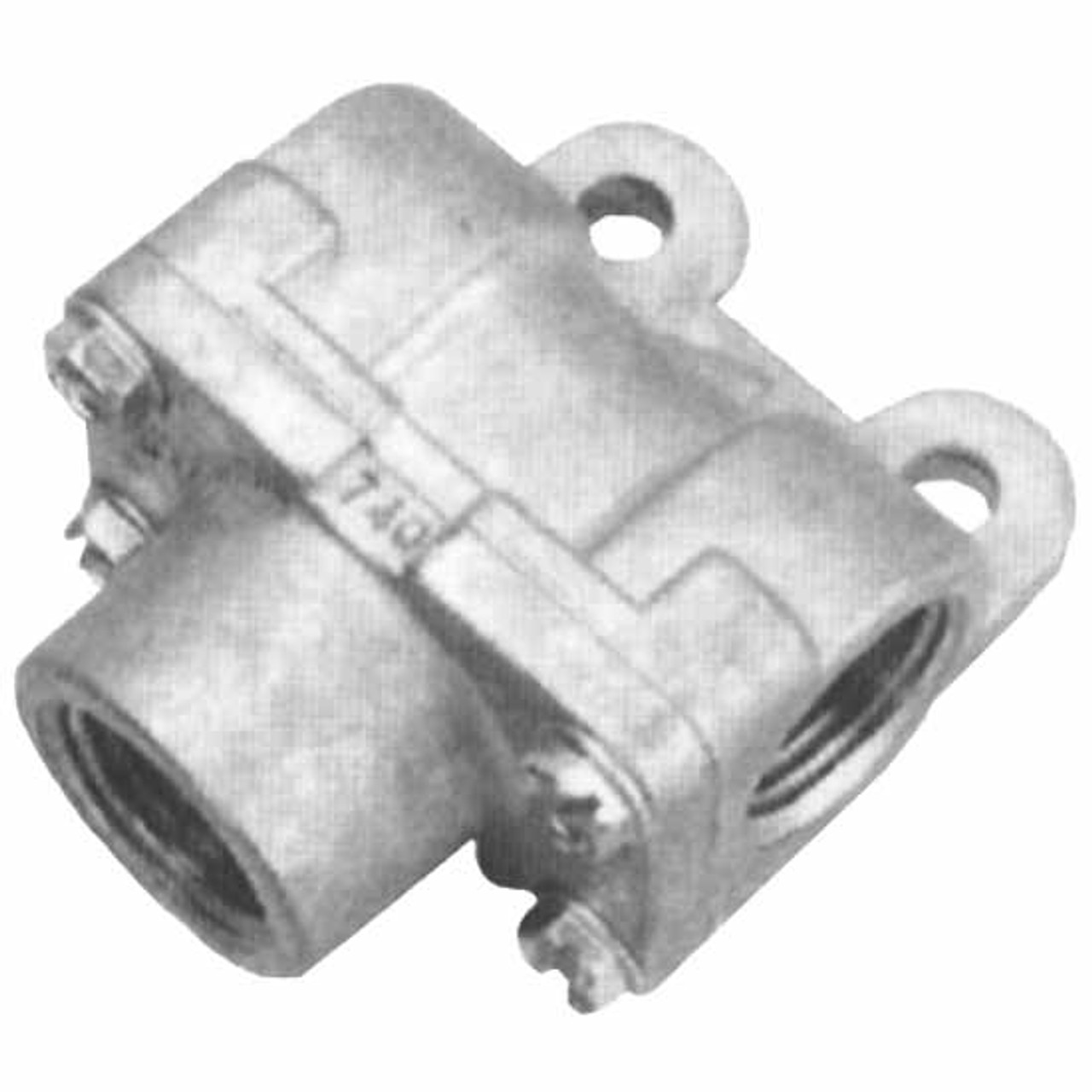

The switching valve system is common in newer Peterbilt trucks. It uses a valve to control fuel flow between tanks. Drivers can switch fuel feed manually or automatically. The valve selects which tank supplies the engine.

This mechanism prevents fuel from flowing freely between tanks. It helps monitor fuel usage from each tank separately. Faults in the valve or its controls can cause fuel tanks not to equalize. Inspecting the valve and wiring is crucial for troubleshooting. Replacing faulty parts restores proper fuel flow.

Credit: rawze.com

Common Causes Of Unequal Fuel Levels

Unequal fuel levels in Peterbilt trucks cause uneven fuel use and can lead to running out of fuel unexpectedly. Understanding common causes helps in quick diagnosis and repair. These issues often arise from mechanical or electrical faults affecting fuel flow between tanks.

Faulty Selector Valve

The selector valve controls fuel flow between tanks. A faulty valve can get stuck or fail to switch properly. This stops fuel from moving to the second tank. The truck then uses fuel only from one tank, causing imbalance.

Damaged Wiring And Connectors

Wiring and connectors link the fuel system components to the control unit. Damage or corrosion can disrupt signals. This leads to incorrect valve operation or pump control. As a result, the fuel tanks fail to equalize correctly.

Blocked Transfer Pump

The transfer pump moves fuel from one tank to another. Blockages or pump failure prevent fuel transfer. This causes one tank to empty faster than the other. Cleaning or replacing the pump resolves the issue.

Symptoms Of Fuel Tank Imbalance

Fuel tank imbalance in Peterbilt trucks can cause several noticeable issues. These symptoms often affect fuel usage and gauge accuracy. Spotting these signs early helps prevent breakdowns and costly repairs.

Fuel Only Drawn From One Tank

The truck pulls fuel from just one tank instead of both. This happens when the selector valve or transfer pump fails. Fuel flow from the second tank gets blocked. The engine runs solely on the first tank’s fuel supply.

Premature Emptying Of First Tank

The first tank empties faster than normal. The second tank remains full or nearly full. This uneven fuel use means the fuel system is not balanced. The truck may stop unexpectedly if the first tank runs dry.

Inconsistent Fuel Gauge Readings

The fuel gauges show different levels on each tank. The readings may jump or behave erratically. This confuses the driver about the real fuel amount. Faulty sensors or wiring can cause this inconsistency.

Credit: www.youtube.com

Quick Fixes For Fuel Tank Equalization

Fuel tank equalization issues on a Peterbilt truck can disrupt your work. Quick fixes save time and prevent bigger problems. Focus on key parts that affect fuel flow and balance.

Inspect And Clean Selector Valve

The selector valve controls fuel flow between tanks. Dirt or debris can block its operation. Remove the valve carefully. Clean it with a suitable solvent. Check for stuck or worn parts. Reinstall and test the valve to ensure smooth switching.

Check And Repair Wiring

Faulty wiring may stop the selector valve or pump from working. Inspect all wires connected to these parts. Look for frayed, loose, or corroded wires. Use a multimeter to test for continuity. Replace or repair damaged wiring to restore electrical flow.

Test And Replace Transfer Pump

The transfer pump moves fuel from one tank to another. A failing pump can cause unequal fuel levels. Test the pump by listening for noise or checking pressure. Replace the pump if it shows signs of failure. Ensure the new pump matches your truck’s specifications.

Preventive Maintenance Tips

Preventive maintenance plays a key role in keeping Peterbilt fuel tanks equalizing properly. Small, regular checks help avoid bigger problems later. Staying on top of fuel system care ensures smooth operation and longer fuel tank life.

Regular Fuel System Inspections

Inspect fuel tanks and lines often for leaks or damage. Check the fuel selector valve and transfer pump for proper function. Look for cracks or corrosion that might block fuel flow. Early detection of issues saves time and money.

Keep Breather Vents Clear

Breather vents let air flow in and out of fuel tanks. Blocked vents cause pressure problems and prevent tanks from equalizing. Clean vents regularly to remove dirt and debris. Use compressed air or a soft brush for best results.

Use Quality Fuel Filters

Fuel filters trap dirt and rust before fuel reaches the engine. Low-quality filters may clog quickly and reduce fuel flow. Choose filters made for Peterbilt trucks. Replace filters on schedule to keep fuel clean and tanks working right.

Upgrading Fuel Systems

Upgrading fuel systems in Peterbilt trucks solves many fuel tank equalizing issues. Modern upgrades improve fuel flow and tank management. These changes help keep the fuel system balanced and efficient. They reduce fuel waste and prevent engine problems caused by uneven fuel levels.

Installing High Flow Return Flow Splitters

High flow return flow splitters help balance fuel between tanks. They increase the return fuel flow rate to each tank. This allows fuel to circulate properly and prevents one tank from running dry. Splitters fit easily into existing fuel lines. They keep fuel pressures stable and improve tank equalization.

Switching To Electronic Valve Controls

Electronic valve controls replace manual or mechanical valves. They use sensors and computers to manage fuel flow precisely. These controls switch fuel between tanks automatically and smoothly. They detect tank levels and adjust fuel flow to keep tanks balanced. Electronic valves reduce wear and avoid fuel starvation problems.

Fuel Efficiency Benefits

Fuel tanks not equalizing in Peterbilt trucks can affect fuel efficiency in several ways. Proper fuel balance ensures the truck runs smoothly and uses fuel wisely. Understanding these benefits helps drivers maintain their trucks better and save money on fuel.

Balanced Fuel Usage

When fuel tanks equalize, fuel flows evenly between both tanks. This balance prevents one tank from emptying too fast. The engine draws fuel evenly, improving overall fuel use. Balanced fuel usage means less waste and better mileage on the road.

Reduced Risk Of Running Out Of Fuel

Unequal fuel levels can cause one tank to run dry quickly. This leads to unexpected stops and delays. Equalizing tanks reduce the chance of running out. Drivers can rely on accurate fuel readings and plan trips better. This lowers the risk of emergencies on long hauls.

Extended Fuel System Lifespan

Fuel system parts work harder if tanks do not equalize. Pumps and valves may wear out faster from uneven fuel flow. Keeping tanks balanced reduces stress on these parts. This helps avoid costly repairs and keeps the truck running longer. A well-maintained fuel system saves money over time.

Credit: www.4statetrucks.com

Frequently Asked Questions

Why Is My Peterbilt Only Drawing Fuel From One Tank?

Your Peterbilt may only draw fuel from one tank due to a faulty selector valve or transfer pump. Check the valve, switch wiring, and connectors for damage or corrosion. A stuck valve blocks fuel flow from the second tank, causing the truck to use only one tank’s fuel.

How Do Dual Fuel Tanks Work On Semi-trucks?

Dual fuel tanks connect via a balance pipe or use a switching valve. Balance pipes equalize fuel levels automatically. Switching valves let drivers select which tank supplies fuel. Modern systems often use electronic controls for safe, efficient fuel flow between tanks.

What Causes Pressure Build Up In A Diesel Fuel Tank?

Pressure builds in a diesel fuel tank due to fuel expansion from heat, blocked vent lines, or faulty pressure relief valves.

What’s The Difference Between A 379 Peterbilt And A 389 Peterbilt?

The 379 Peterbilt features a traditional design with a narrower hood. The 389 offers a wider hood and updated styling. Both share similar performance but differ mainly in exterior appearance and aerodynamics.

Why Are Peterbilt Fuel Tanks Not Equalizing Properly?

Fuel tanks may not equalize due to a clogged balance pipe or a faulty selector valve blocking fuel flow.

Conclusion

Peterbilt fuel tanks not equalizing can cause uneven fuel use and delays. Checking the selector valve and wiring helps find common issues fast. Regular maintenance keeps the fuel system working smoothly and avoids costly problems. Understanding how dual tanks work makes troubleshooting easier.

Staying proactive ensures your Peterbilt runs efficiently on every trip. Keep an eye on fuel levels to prevent unexpected stops. Simple fixes often restore balance between tanks quickly and safely.