When it comes to polishing your car or working on any surface that needs a flawless finish, choosing the right pad can make all the difference. You might be wondering—should you go for microfiber or foam pads?

Each has its own strengths, and picking the wrong one could mean more work or less shine than you hoped for. You’ll discover exactly how microfiber and foam pads differ, when to use each, and how they affect your results.

By the end, you’ll feel confident about which pad suits your needs best, saving you time and effort while achieving that perfect finish you want. Keep reading to unlock the secrets behind microfiber vs foam pads and take your polishing game to the next level.

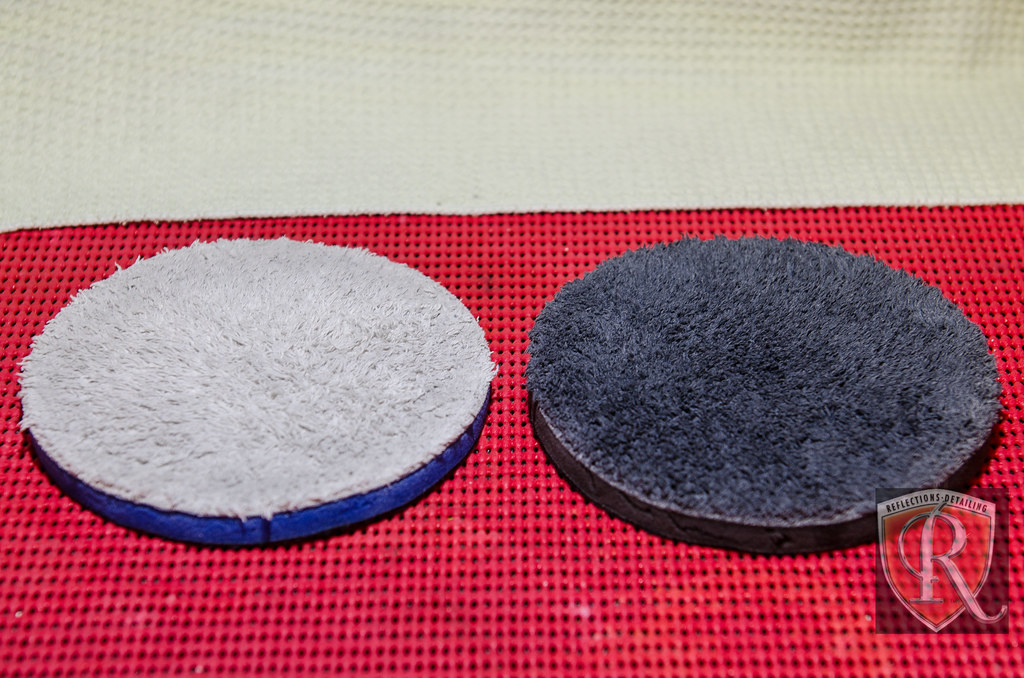

Microfiber Pads

Microfiber pads offer a unique approach to polishing and buffing tasks. They stand out because of their construction and performance. These pads are designed to provide efficient cutting power and distinct heat behavior. Understanding their features helps in choosing the right pad for your project.

Material And Construction

Microfiber pads are made from densely packed synthetic fibers. These fibers are woven tightly to create a strong surface. The construction allows the pads to hold more product than foam pads. This design helps in distributing pressure evenly on the surface.

Cutting Power

Microfiber pads deliver strong cutting power. They remove imperfections faster than many foam pads. This makes them ideal for heavy correction work. The fibers grip the paint surface and lift away defects efficiently. They often require fewer passes to achieve results.

Heat Generation

Microfiber pads tend to generate more heat during use. The dense fibers cause friction that raises the temperature. This heat can speed up polishing but needs careful control. Overheating may damage paint, so monitoring temperature is important.

Best Uses

Microfiber pads work best for cutting and compounding tasks. They excel in removing scratches, oxidation, and heavy swirls. Professionals use them for initial polishing stages. They also suit projects needing fast correction without sacrificing control.

Credit: www.detailedimage.com

Foam Pads

Foam pads are a popular choice for many car enthusiasts and detailers. They offer a soft, flexible surface that works well with polishing machines. These pads come in different densities and textures, allowing for various levels of polish and finish. Foam pads are known for their smooth application and ability to enhance the shine of a vehicle’s paint.

Material And Texture

Foam pads are made from polyurethane foam. This material is soft and compressible. Foam pads have different textures, such as open-cell or closed-cell structures. Open-cell foam is more porous and softer, which helps with heat dissipation. Closed-cell foam is denser and firmer, offering more cutting power. The texture affects how the polish spreads and how aggressive the pad is.

Finishing Ability

Foam pads excel at finishing tasks. They provide a smooth, even application of polish or wax. The soft texture reduces swirl marks and holograms. Foam pads help create a deep, glossy shine on the paint surface. They are less likely to cause damage compared to more aggressive pads. This makes them ideal for delicate paint finishes.

Product Application

Foam pads work well with liquid or cream polishes. Their absorbent nature holds the product evenly. They distribute polish smoothly over large areas. Foam pads can be used for applying wax, sealants, and glazes. Their flexibility allows them to conform to curved surfaces easily. This ensures consistent coverage on all parts of the vehicle.

Best Uses

Foam pads suit finishing and light polishing jobs best. They are perfect for removing minor imperfections and enhancing gloss. Foam pads work well on painted surfaces that need gentle care. Detailers use them for applying finishing polishes or waxes. They are also good for maintaining a vehicle’s shine after more aggressive corrections.

Performance Comparison

Comparing microfiber and foam pads reveals key differences in how they perform during polishing tasks. Each pad type offers unique traits that affect cutting power, finish quality, heat management, and durability. Understanding these factors helps choose the right pad for specific detailing needs.

Microfiber pads often excel in aggressive polishing, while foam pads provide smoother finishes. Heat retention and pad lifespan also vary, influencing overall effectiveness. The following breakdown highlights these performance aspects clearly.

Aggressiveness And Cutting

Microfiber pads cut more aggressively than foam pads. Their fibers lift and remove deeper scratches faster. Foam pads tend to be softer and less abrasive. This makes foam better suited for light polishing and swirl removal. Microfiber works well for heavy correction jobs needing strong cutting power.

Finishing Quality

Foam pads deliver a finer finish with fewer holograms and less haze. They distribute polish evenly across the surface. Microfiber pads can leave slight micro-marring if not used carefully. Foam is ideal for the final polishing step to achieve a glossy, smooth look. Microfiber is best for initial correction rather than finishing.

Heat Retention

Microfiber pads retain more heat during use than foam pads. This can speed up polish drying but risks overheating the paint. Foam pads stay cooler and reduce heat buildup. Cooler pads lower the chance of paint damage. Proper speed and pressure control are important with microfiber to avoid heat issues.

Durability

Microfiber pads are generally more durable and maintain shape longer. Their dense fibers resist breakdown from polishing compounds. Foam pads wear out faster and compress with use. Foam may lose cutting and finishing ability sooner. Microfiber pads offer better longevity, making them cost-effective over time.

Choosing The Right Pad

Choosing the right pad is key to a great polishing job. The pad you pick affects the finish and ease of use. Microfiber and foam pads each have strengths. Knowing how to match them to your task helps you get the best result.

Type Of Polishing Job

Microfiber pads work well for cutting and heavy correction. They remove deep scratches and oxidation faster. Foam pads are softer and better for finishing. They create a smooth, glossy finish without removing too much paint. Select microfiber for aggressive polishing. Choose foam for light polishing or final buffing.

Product Compatibility

Check the polish or compound you use. Some products work better with microfiber pads. These pads hold more product and provide strong cutting power. Foam pads spread polish evenly and prevent waste. For thin liquids or spray products, foam pads apply better. For thick compounds, microfiber pads work best.

Machine Type

Microfiber pads suit dual-action and rotary polishers. They handle high speed and pressure well. Foam pads are gentle and fit all machine types. Use foam pads for random orbital machines to avoid damage. Match the pad type to your machine for safe and effective polishing.

Skill Level

Beginners find foam pads easier to control. Foam pads reduce the risk of paint damage. Microfiber pads need more experience to avoid swirl marks. Practice is key before using microfiber pads on valuable vehicles. Start with foam pads to build confidence and skill.

Maintenance And Care

Proper maintenance and care keep both microfiber and foam pads effective for longer. Cleaning after each use stops residue build-up. Good storage prevents damage and keeps pads fresh. Understanding what affects pad lifespan helps you get the best value.

Cleaning Techniques

Rinse pads in warm water to remove excess product. Use a gentle brush to clean deeply without tearing fibers. Avoid harsh detergents; mild soap works best. Let pads air dry completely before storing. Do not use a dryer or direct heat, as it may damage the pad.

Storage Tips

Store pads in a clean, dry place away from sunlight. Keep them in a sealed container or bag to avoid dust. Do not stack wet pads, as this causes mildew. Separate microfiber and foam pads to maintain their shape. Avoid compressing pads under heavy objects.

Longevity Factors

Frequent cleaning extends pad life by preventing buildup. Avoid using aggressive chemicals that degrade pad material. Use the right pad for the job to reduce wear. Proper drying stops mold and unpleasant smells. Regular inspection helps spot damage early for timely replacement.

Credit: www.youtube.com

User Experiences

User experiences reveal much about microfiber and foam pads. These insights help users choose the right pad for their needs. Real feedback from users shows how each pad performs in daily tasks. Understanding these experiences guides beginners and experts alike.

Professional Opinions

Many professionals prefer microfiber pads for cutting tasks. They say microfiber cuts faster and removes defects well. Foam pads get praise for finishing work. Experts note foam pads provide a smooth, even finish. Some pros combine both pads for best results. They start with microfiber, then switch to foam for polishing. Professionals also mention microfiber pads run hotter during use. Foam pads stay cooler, reducing heat risk on surfaces.

Common Preferences

Many users choose microfiber pads for heavy correction jobs. They like how microfiber handles thick compounds easily. Foam pads appeal to those who want a gentle polish. Users say foam pads spread polish evenly without streaks. Beginners often start with foam pads for their ease of use. Experienced users prefer microfiber for speed and power. Some users enjoy using both types depending on the job. Microfiber is common for aggressive work, foam for final shine.

Troubleshooting Issues

Some users report microfiber pads can generate heat too fast. This may cause polish drying or surface damage. To avoid this, users suggest working at lower speeds. Foam pads sometimes absorb too much product, wasting polish. Users recommend applying polish sparingly on foam pads. Another issue is pad durability. Microfiber pads may wear out faster with heavy use. Foam pads often last longer but can tear if handled roughly. Proper cleaning and care extend pad life for both types.

Credit: autogeekonline.net

Frequently Asked Questions

Are Foam Or Microfiber Pads Better?

Microfiber pads cut more aggressively and heat up faster, ideal for heavy correction. Foam pads finish smoother, perfect for polishing and finishing. Choose microfiber for cutting and foam for refining to achieve the best results.

Is Foam Applicator Better Than Microfiber?

Foam applicators suit light, thin products for smooth finishes. Microfiber works better with thicker, heavier products needing more coverage.

Is Microfiber The Same As Foam?

Microfiber and foam are different materials. Microfiber pads cut more aggressively, while foam pads provide a smoother finish. Microfiber generates more heat, making it ideal for heavy correction, whereas foam suits light polishing and finishing tasks.

Which Is Better, Memory Foam Or Microfiber?

Microfiber offers stronger cutting power and durability, while memory foam provides better cushioning and comfort. Choose based on your needs.

What Is The Main Difference Between Microfiber And Foam Pads?

Microfiber pads are more aggressive for cutting, while foam pads provide a smoother finish.

Conclusion

Choosing between microfiber and foam pads depends on your polishing needs. Microfiber pads cut more aggressively and remove defects faster. Foam pads provide a smoother finish and work well for light polishing. Both types have unique strengths that suit different tasks.

Consider the product type and desired result before picking a pad. Using the right pad improves your detailing process and final look. Experimenting with both can help find what fits your style best. Quality polishing starts with choosing the correct pad for the job.