Are you thinking about upgrading to a Melling high volume oil pump? Before you make that switch, it’s important to know that these pumps can cause some serious problems if they’re not the right fit for your engine.

You might expect better performance, but instead, you could face issues like excessive oil pressure, worn distributor gears, or even damage to vital engine parts. You’ll discover exactly what problems can arise with Melling high volume oil pumps, why they happen, and when using one makes sense—or doesn’t.

Keep reading to protect your engine and make the smartest choice for your ride.

Common Pump Issues

Melling high volume oil pumps can improve oil flow but may cause common problems. These issues often affect engine performance and longevity. Understanding these problems helps in proper maintenance and avoiding costly repairs.

Each problem links to the pump’s design and how it interacts with engine parts. Recognizing signs early can prevent bigger failures and keep the engine running smoothly.

Distributor Gear Wear

The distributor gear faces extra strain from a high volume pump. It needs more force to turn the pump. This force can cause the gear teeth to wear out faster. Worn gears may lead to mis-timing and engine performance loss. In some engines, the camshaft may also suffer damage.

Excessive Oil Pressure

A high volume pump can push oil at very high pressure. Engines not built for this pressure may have oil backing up in passages. This backup reduces cooling and lubrication efficiency. Excessive pressure also risks damaging seals and gaskets. Over time, it can wear out pump parts and other components.

Pump Shaft Damage

The pump shaft handles all the power from the distributor gear. Increased load from a high volume pump can bend or break the shaft. Damage here stops oil circulation, leading to engine failure. Shaft problems also create noise and reduce pump efficiency.

Engine Component Stress

Extra oil flow stresses many engine parts. Bearings and seals face higher forces than designed. This stress causes faster wear and possible leaks. Overloaded components may fail, causing costly engine damage. Engines without proper upgrades should avoid high volume pumps.

Parasitic Horsepower Loss

High volume pumps use more engine power to run. This power loss reduces overall engine output. The extra load is called parasitic horsepower loss. It lowers fuel efficiency and performance. For daily driving, this loss often outweighs benefits.

Credit: www.chevyhardcore.com

Damage Risks

Using a Melling high volume oil pump in an engine not built for it can cause serious damage. The pump pushes more oil than usual, which may lead to multiple risks. These risks affect the engine’s health and its parts’ durability. Understanding these damage risks helps in avoiding costly repairs and maintaining engine performance.

Oil Backup Effects

Excess oil flow can cause oil to back up in the system. This backup creates pressure in places it should not be. Oil backup limits the oil’s ability to move freely. It can block oil passages and reduce lubrication. This blockage also stops the oil from cooling the engine properly. Over time, this leads to poor engine performance and possible damage.

Premature Component Failure

A high volume oil pump can put extra stress on engine parts. The distributor gear and pump shaft may wear out faster. Increased oil pressure may cause seals and gaskets to fail early. Bearings and other moving parts may suffer from too much pressure. This stress shortens the life of many engine components. Replacing these parts often means costly repairs and downtime.

Heat Dissipation Problems

Proper heat removal relies on steady oil flow. Too much oil flow can cause heat to build up in some areas. This heat buildup affects engine cooling and increases wear. Oil that is too hot cannot protect engine parts well. Overheated oil loses its ability to lubricate. This condition speeds up engine wear and can cause breakdowns.

When To Use High Volume Pumps

High volume oil pumps are not for every engine. They serve a specific purpose in certain conditions. Knowing when to use them helps avoid engine damage. These pumps move more oil, which suits engines with special needs. Using them correctly ensures better lubrication and engine life.

High-rpm Engine Needs

Engines that run at very high RPMs demand more oil flow. High volume pumps deliver this extra oil quickly. This prevents oil starvation at high speeds. It keeps all parts well-lubricated during intense operation. Without enough oil, engine parts wear out fast.

Engines With Solid Lifters

Solid lifters need more oil pressure than hydraulic lifters. High volume pumps provide the needed oil flow to keep them working. Proper lubrication reduces noise and wear. These pumps help maintain steady oil pressure for solid lifters.

Larger Bearing Clearances

Engines with larger bearing clearances require more oil flow. High volume pumps supply enough oil to fill the gaps. This prevents metal-to-metal contact inside the engine. Correct oil flow ensures bearings stay cool and last longer.

Credit: jprstudies.org

Alternatives To High Volume Pumps

Choosing the right oil pump matters for engine health and performance. High volume pumps suit some builds but cause issues in others. Alternatives provide safer, effective oil flow without extra risks. These options keep your engine running smoothly without added wear or pressure problems.

Stock Pump Benefits

Stock oil pumps match the engine’s original design. They maintain proper oil pressure for daily driving. These pumps avoid excessive stress on gears and shafts. Using a stock pump helps prevent early wear and damage. They work well with factory tolerances and clearances. Stock pumps require less maintenance and fewer repairs.

Fixing Underlying Wear Issues

Addressing engine wear reduces the need for a high volume pump. Worn bearings or seals cause low oil pressure. Repairing these parts restores normal oil flow. Cleaning clogged oil passages also improves pressure. Fixing root problems protects engine parts from damage. This approach is cheaper and extends engine life.

Electric Oil Pumps

Electric oil pumps offer precise control of oil flow. They provide steady pressure regardless of engine speed. These pumps help during cold starts and high RPMs. Electric pumps reduce mechanical load on the engine. Installation is simpler in some cases. They are a good choice for specific performance upgrades.

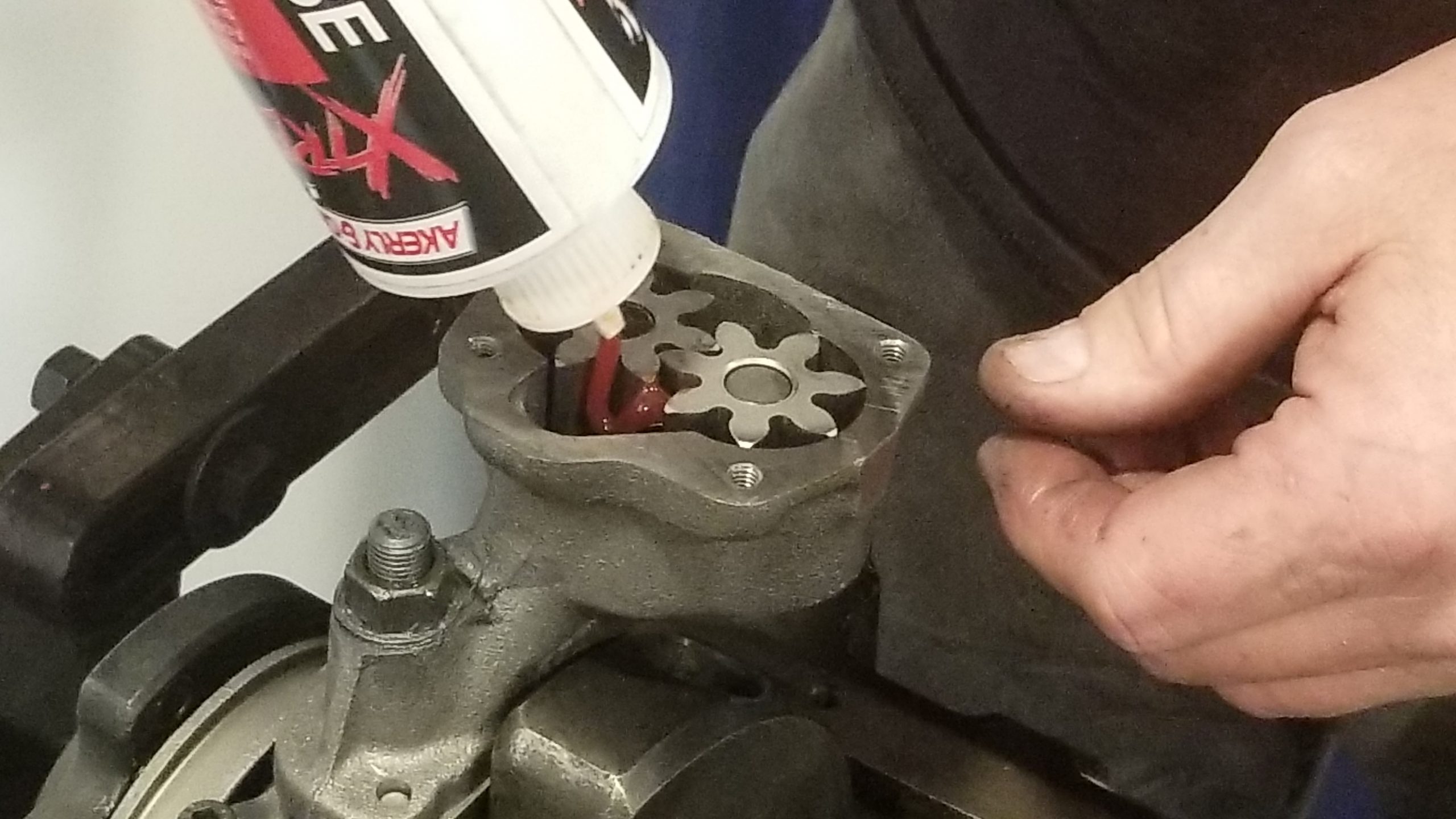

Installation Tips

Installing a Melling High Volume Oil Pump requires care and attention. Proper installation helps avoid common problems that can damage your engine. Follow these tips to ensure your pump works efficiently and lasts longer. Use the right parts and monitor performance closely after installation.

Matching Pump To Engine Specs

Choose a pump that fits your engine’s size and type. A high-volume pump is not always best for stock engines. Check the engine manual for recommended oil flow rates. Using the wrong pump may cause oil pressure issues and damage parts. Match the pump to your engine’s clearances and performance needs.

Avoiding Distributor Gear Damage

The distributor gear can wear out faster with a high-volume pump. High pressure creates more force on the gear and shaft. Inspect the distributor gear for strength before installation. Consider upgrading to a hardened gear to prevent early failure. Proper alignment during installation reduces stress on these components.

Monitoring Oil Pressure

Check oil pressure after installing the pump. High oil pressure can harm seals and gaskets. Use a reliable gauge to track pressure levels regularly. Keep pressure within the engine’s safe range. Too high or too low pressure signals a problem that needs fixing.

Credit: www.onallcylinders.com

Maintenance Advice

Proper maintenance is key to avoiding common issues with Melling High Volume Oil Pumps. Regular care helps keep the pump working efficiently and extends its lifespan. Neglecting maintenance can cause serious problems, including reduced oil flow and engine damage. Follow these simple steps to ensure your oil pump stays in good condition.

Regular Inspection

Check the oil pump regularly for signs of wear or damage. Look for leaks, cracks, or unusual noises during operation. Inspect the pump’s gears and housing to catch problems early. Early detection helps prevent costly repairs and engine failures.

Oil Quality Checks

Use clean, high-quality oil suitable for your engine. Dirty or low-grade oil can cause blockages and wear inside the pump. Change the oil and filter on schedule. Good oil helps the pump work smoothly and protects engine parts from damage.

Replacing Worn Parts

Replace any worn or damaged parts immediately. Pay attention to gears, shafts, and seals. Using worn parts reduces pump efficiency and may lead to failure. Keep spare parts handy for quick replacements and avoid long downtime.

Frequently Asked Questions

Will A High Volume Oil Pump Hurt A Stock Engine?

A high volume oil pump can harm a stock engine by stressing the distributor gear and causing excessive oil pressure. It may lead to premature wear, pump damage, and reduced engine lifespan. Use high volume pumps only in modified, high-RPM engines needing increased oil flow.

Are Melling Oil Pumps Any Good?

Melling oil pumps are reliable and perform well in most applications. They suit both stock and high-performance engines when properly matched. Avoid high-volume pumps on stock engines to prevent damage. Choose Melling for quality, but ensure pump type fits your engine’s needs for optimal performance and longevity.

What Is Better, A High Volume Or High Pressure Oil Pump?

A high-volume oil pump suits high-RPM or modified engines needing more flow. A high-pressure pump fits stock engines requiring consistent pressure. Choose based on engine type to avoid damage and ensure optimal lubrication.

How To Tell If A High Pressure Oil Pump Is Bad?

Signs of a bad high pressure oil pump include low oil pressure, engine noise, metal shavings in oil, and poor engine performance. Check for leaks and unusual noises from the pump area. Consistent oil pressure drops or warning lights also indicate pump failure.

What Are Common Problems With Melling High Volume Oil Pumps?

Melling high volume oil pumps often cause distributor gear wear and excessive oil pressure issues.

Conclusion

Melling high volume oil pumps can cause issues if not matched correctly. They put extra strain on distributor gears and may raise oil pressure too much. This can lead to gear wear, pump damage, and reduced engine life. These pumps suit high-RPM or modified engines needing more oil flow.

Stock engines usually do not benefit and may suffer harm. Always check compatibility before upgrading your oil pump. Proper maintenance and correct parts keep your engine running smoothly and safely. Choose wisely to avoid costly repairs down the road.