Is your car’s engine idling roughly? It might be time for an idle air control repair.

This component plays a crucial role in maintaining your car’s engine idle speed. Understanding idle air control (IAC) repair can save you from potential headaches. The IAC valve regulates the engine’s idle speed by controlling the amount of air that bypasses the throttle plate.

When it fails, your car might stall or idle erratically. Fixing this issue requires some basic knowledge about car engines and a bit of patience. In this blog post, we’ll explore the importance of the IAC valve, signs of its failure, and steps to repair it. This guide will help you maintain your vehicle’s performance and avoid unexpected breakdowns. Let’s dive in and get your car running smoothly again.

Introduction To Idle Air Control

The idle air control (IAC) valve is essential for engine performance. It regulates the engine’s idle speed, ensuring smooth operation. If the IAC fails, the engine might stall or run rough. Understanding the IAC can help maintain your vehicle.

What Is Idle Air Control?

The IAC valve is a component in fuel-injected engines. It controls the air that bypasses the throttle plate. This helps the engine maintain a stable idle speed. The IAC valve adjusts to changes in engine load, temperature, and other conditions.

Importance In Engine Performance

A well-functioning IAC valve keeps the engine running smoothly. It prevents stalling and rough idling. Proper idle speed improves fuel efficiency and reduces emissions. A faulty IAC valve can cause various engine problems. Regular maintenance ensures optimal performance.

Symptoms Of A Faulty Idle Air Control Valve

A faulty idle air control valve can cause rough idling, stalling, and irregular engine RPMs. Poor acceleration and increased fuel consumption may also occur. Regular maintenance can help prevent these issues.

The idle air control (IAC) valve is vital for your engine’s performance. It regulates the idle speed by controlling the airflow to the engine. A faulty IAC valve can cause various issues. Recognizing these symptoms can help you diagnose and fix the problem early.Irregular Idle Speed

One common sign of a faulty IAC valve is irregular idle speed. Your engine may idle too fast or too slow. You might notice the RPM gauge fluctuating. This irregularity can lead to poor engine performance. It can also affect fuel efficiency.Engine Stalling

Another symptom is engine stalling. If the IAC valve is not working, your engine might stall. This happens especially when stopping at traffic lights. It can also occur during low-speed driving. Stalling can be dangerous and frustrating. It’s a clear sign that the IAC valve needs attention. “`Causes Of Idle Air Control Valve Failure

The idle air control (IAC) valve is essential for controlling your car’s engine idle speed. It ensures the engine runs smoothly when the car is not moving. Over time, the IAC valve may fail. Here are some common causes of IAC valve failure:

Dirt And Debris

Dirt and debris can block the IAC valve. This can restrict airflow. When the valve gets clogged, it can’t regulate the engine’s idle speed. This blockage causes rough idling or stalling.

Regular cleaning of the IAC valve helps. It prevents the buildup of dirt and debris. This maintenance can prolong the life of the IAC valve.

Wear And Tear

Wear and tear is another common cause. The IAC valve parts degrade over time. This is especially true for vehicles with high mileage. The internal components can wear out, causing the valve to fail.

Aging parts may lead to erratic idling. This means the engine speed may fluctuate unexpectedly. Replacing the IAC valve when it shows signs of wear can prevent these issues.

| Cause | Effect |

|---|---|

| Dirt and Debris | Blocked valve, rough idling, stalling |

| Wear and Tear | Erratic idling, part failure |

Understanding these causes can help maintain your vehicle. Regular inspections and maintenance are key. Keep your IAC valve clean and in good condition.

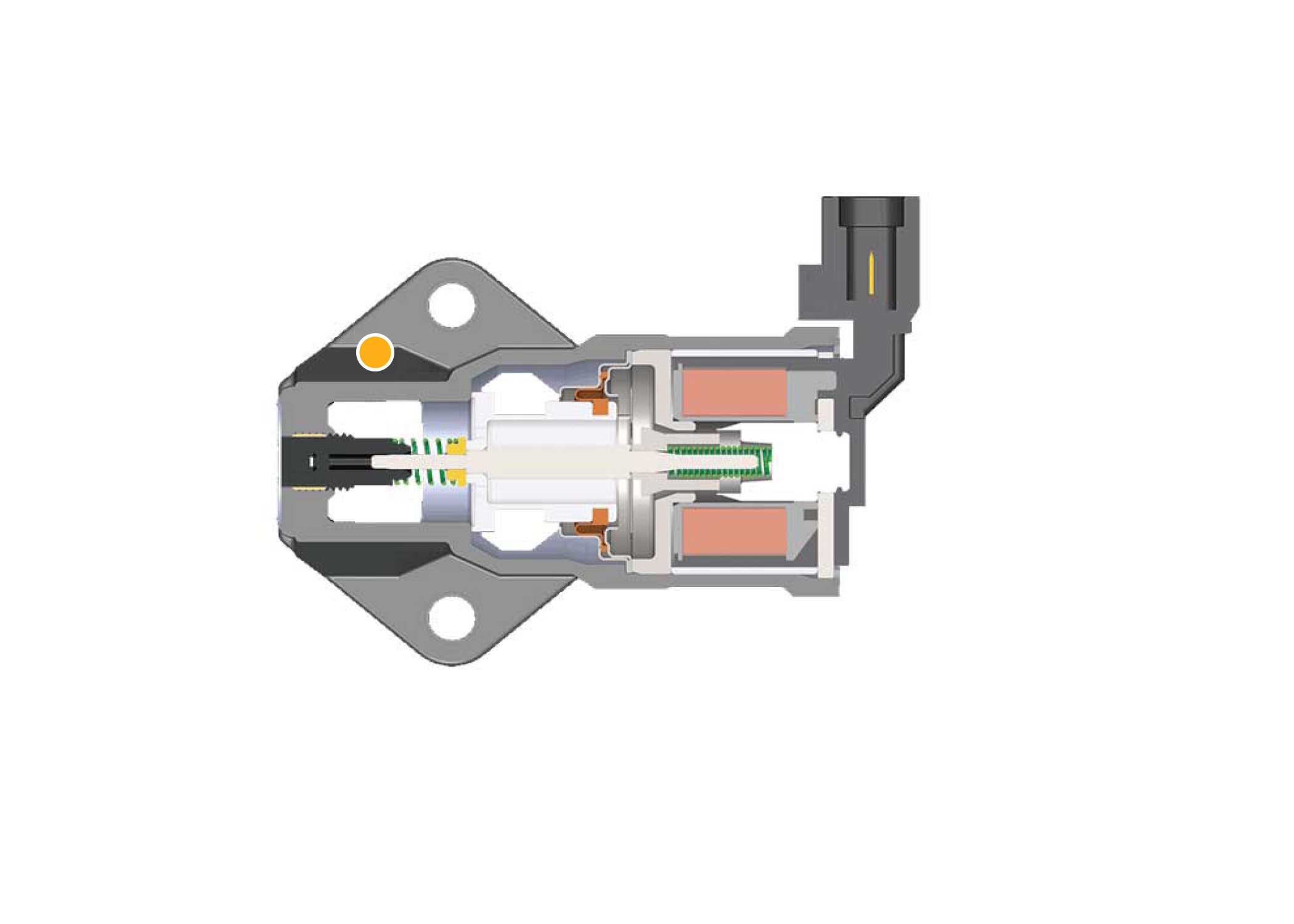

Credit: www.standardbrand.com

Tools Needed For Idle Air Control Repair

Repairing the idle air control valve can seem daunting. But with the right tools, the task becomes manageable. This section will detail the essential and optional tools needed for idle air control repair.

Essential Tools

Some tools are a must-have for this repair. You will need a basic set of screwdrivers. Both flathead and Phillips types are essential. A wrench set is also crucial. Ensure you have various sizes. You will need them to remove bolts and screws. Pliers are another essential tool. They help with gripping and pulling out parts.

A multimeter is necessary. It measures the electrical current. This helps in diagnosing the idle air control valve. Also, have a cleaning solution. It helps clean the valve. Finally, get a gasket scraper. This is used to remove old gaskets. Having these tools will prepare you for the repair.

Optional Tools

Some tools are not essential but can make the job easier. A torque wrench is useful. It ensures bolts are tightened correctly. A vacuum gauge can also be helpful. It checks the vacuum lines for leaks.

Another helpful tool is a flashlight. It helps you see in tight spaces. A diagnostic scanner is also handy. It reads error codes from the car’s computer. This can help in diagnosing the problem. These optional tools can streamline the repair process.

Step-by-step Idle Air Control Valve Repair

Maintaining your vehicle’s idle air control valve is crucial. It ensures smooth engine performance. This guide will help you repair the idle air control valve step-by-step. Follow these instructions for a hassle-free process.

Preparation And Safety Measures

First, gather the necessary tools. You will need a wrench, screwdriver, and replacement valve. Wear safety gloves and goggles. Ensure your vehicle is parked on a flat surface. Disconnect the battery to avoid electrical shocks. Make sure the engine is cool to prevent burns.

Removing The Old Valve

Locate the idle air control valve. It is usually near the throttle body. Use the wrench to loosen the bolts holding the valve. Carefully disconnect the electrical connector. Remove the old valve from its position. Inspect the area for dirt or debris. Clean it if necessary.

Installing The New Valve

Take the new idle air control valve. Align it with the mounting holes. Secure it with the bolts using the wrench. Reconnect the electrical connector. Ensure everything is tight and in place. Reconnect the battery. Start the engine to check if the new valve works properly.

Credit: www.autozone.com

Post-repair Engine Performance Boost

Experiencing an idle air control repair can significantly enhance your engine’s performance. This improvement can be seen in various areas of your vehicle’s functionality. Let’s explore how a repaired idle air control valve boosts your car’s performance in terms of fuel efficiency and engine smoothness.

Improved Fuel Efficiency

One of the main benefits of idle air control repair is better fuel efficiency. A faulty idle air control valve can cause your engine to consume more fuel than necessary. This happens because the engine struggles to maintain a steady idle speed.

After the repair, the engine can regulate the air-fuel mixture more effectively. This leads to optimal fuel consumption. You will notice fewer trips to the gas station and more savings in your pocket.

| Before Repair | After Repair |

|---|---|

| High fuel consumption | Optimal fuel usage |

| Irregular idle speed | Steady idle speed |

Smooth Engine Idle

Another advantage of repairing the idle air control valve is a smoother engine idle. A malfunctioning valve can cause the engine to idle roughly, making the car shake or vibrate.

Post-repair, the engine runs more smoothly. You will experience less vibration and a quieter ride. The car will feel more stable, especially when idling at a stoplight or in traffic.

- Less engine vibration

- Quieter idle

- Increased stability

Overall, fixing the idle air control valve ensures your engine performs better, saving you money and providing a smoother driving experience.

Preventive Maintenance Tips

Keeping your Idle Air Control (IAC) valve in top shape is essential. Preventive maintenance helps avoid unexpected issues and ensures smooth engine performance. Regular cleaning and routine inspections are key practices.

Regular Cleaning

Regular cleaning of the IAC valve is crucial. Dirt and debris can clog the valve. This can cause rough idling or stalling. Use a throttle body cleaner for this task. Spray the cleaner on the valve and use a soft brush. Gently scrub to remove all deposits. Ensure the valve is completely dry before re-installing. Regular cleaning keeps the valve functioning properly.

Routine Inspections

Routine inspections help identify potential issues early. Check the IAC valve and its components. Look for signs of wear or damage. Listen for unusual noises from the valve area. These could indicate a problem. Inspect the wiring and connections. Loose or damaged wires can affect the valve’s performance. Regular inspections help maintain engine efficiency and reliability.

When To Seek Professional Help

Understanding when to seek professional help for idle air control repair is essential. Some issues might seem simple but could lead to complex problems if not addressed correctly. Let’s break down the scenarios where professional intervention is crucial.

Complex Repair Situations

Sometimes, the repair process involves more than just a basic inspection. For instance, if the idle speed fluctuates or the engine stalls frequently, it can indicate deeper issues. Here are some situations where professional help is necessary:

- Frequent engine stalling despite cleaning the idle air control valve.

- Unusual noises from the engine area.

- Check engine light remains on even after resetting.

- Electrical or wiring issues connected to the idle air control system.

Experts have the right tools and diagnostic equipment. They can identify and fix these complex problems efficiently. Attempting to repair without proper knowledge can worsen the issue.

Persistent Issues

If you notice persistent issues, it is time to consult a professional. Persistent problems can include:

- Constantly fluctuating idle speed.

- Poor fuel economy despite regular maintenance.

- Difficulty starting the engine.

- Idle speed does not adjust in response to engine load changes.

These issues might indicate deeper engine or sensor problems. Professional mechanics can perform thorough diagnostics. They can provide a long-term solution to these persistent issues. Ignoring these signs can lead to more significant engine damage.

Credit: www.repairconnector.com

Frequently Asked Questions

What Is An Idle Air Control Valve?

The Idle Air Control Valve (IACV) regulates engine idle speed. It manages the airflow when the throttle is closed.

How Do You Know If The Iac Valve Is Faulty?

Symptoms include rough idle, stalling, or high idle. Check engine light may turn on.

Can You Drive With A Bad Idle Air Control Valve?

Driving with a bad IACV is possible but not recommended. It can cause stalling or engine damage.

How Much Does It Cost To Replace An Iac Valve?

Replacing an IACV typically costs between $100 and $300, including parts and labor.

Can I Clean The Idle Air Control Valve Myself?

Yes, you can clean the IACV. Use a cleaner and a brush. Be gentle to avoid damage.

Conclusion

Fixing your idle air control valve improves your car’s performance. It’s a simple task that you can do yourself or with a mechanic’s help. Regular maintenance prevents bigger issues down the road. Your car will run smoother and more efficiently.

Take action now to ensure a better driving experience. Don’t ignore the signs of a faulty idle air control valve. Your car and wallet will thank you later. Happy driving!