If you’re considering using Fluid Film for rust protection or lubrication, you might have come across some mixed reviews and complaints. You’re probably wondering, “Is Fluid Film really as good as it claims?

Are there hidden downsides I should know about before using it on my vehicle or equipment? ” This article will help you understand the common Fluid Film complaints, what causes them, and how you can avoid costly mistakes. By the time you finish reading, you’ll have a clearer picture of whether Fluid Film is right for your needs and how to use it safely to protect your investment.

Don’t let confusion or misinformation hold you back—let’s get to the facts!

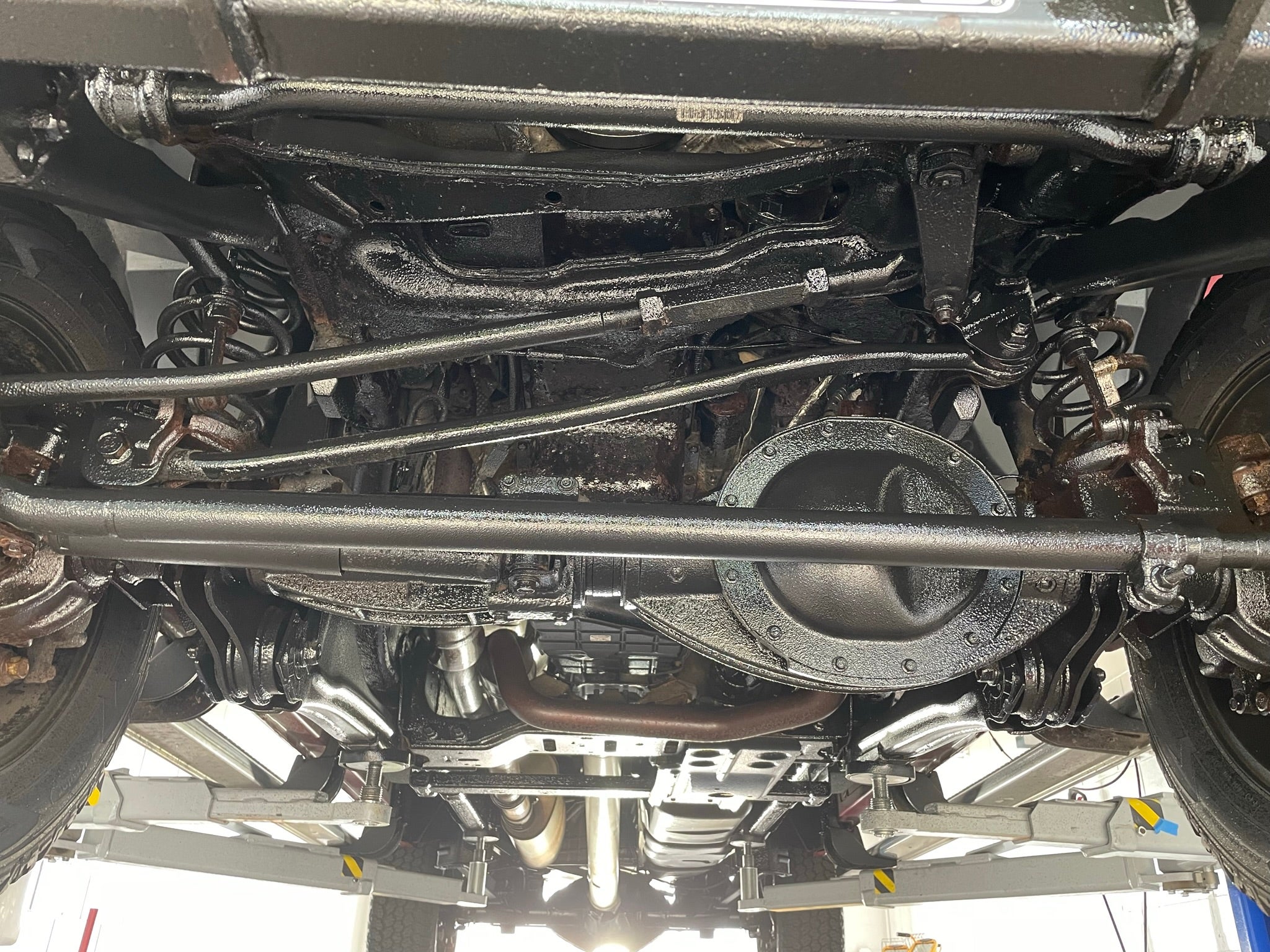

Credit: www.ultimateundercoating.com

Common Fluid Film Complaints

Fluid Film is a popular rust prevention spray used in many industries. Despite its benefits, users report some common complaints. These issues mostly relate to certain materials and vehicle parts. Understanding these complaints helps users avoid damage and get better results.

The following sections highlight frequent concerns about Fluid Film. They focus on rubber and plastics, brakes and exhaust, engine and drivetrain, and electrical parts. Each area has specific problems to watch for.

Issues With Rubber And Plastics

Fluid Film can cause problems with non-oil-resistant rubber parts. These include bushings, hoses, and seals. The spray may cause swelling, cracking, or failure. Older rubber is especially vulnerable. Some plastics can also be affected, though most modern plastics are safe. Users should test on a small area first.

Concerns Around Brakes And Exhaust

Applying Fluid Film to brake parts is risky. It can reduce friction on rotors, pads, and calipers. This leads to poor braking performance and safety issues. The exhaust system is another no-go zone. High heat burns off Fluid Film quickly. It may also cause unpleasant odors or residue buildup.

Problems On Engine And Drivetrain

Fluid Film should not be sprayed on engine oil pans or transmission cases. It can affect oil seals and cause leaks. Drive belts are also sensitive. The spray causes slippage and damage to belts. Avoid spraying cooling lines and sensitive moving parts to prevent mechanical issues.

Electrical Component Risks

Fluid Film is generally safe on battery terminals and connectors. Still, it should not be used on exposed electrical components. Excess lubrication can cause shorts or corrosion. Avoid spraying sensitive circuits and sensors. Use with caution near wiring harnesses and electronic modules.

Areas To Avoid Spraying

Using Fluid Film is great for rust prevention and lubrication. Yet, it is important to spray it only on the right areas. Certain parts can be damaged or lose function if Fluid Film touches them. Knowing where not to spray saves time and avoids problems.

Non-oil-resistant Rubber And Plastics

Fluid Film can cause non-oil-resistant rubber to swell and break. This includes some bushings, hoses, and seals. Older rubber parts are more sensitive. Most modern plastics and paints handle Fluid Film well. Still, avoid spraying on plastics that might react badly.

Brake System Components

Do not spray Fluid Film on brake rotors, pads, or calipers. It can reduce brake performance and cause dangerous slippage. Keep brake parts clean and free from any lubricant or oily substance.

Exhaust System Parts

The exhaust system gets very hot. Fluid Film sprayed on it will burn off quickly. It also can cause unpleasant smells. Avoid spraying any pipes, mufflers, or manifolds to prevent damage.

Drive Belts And Sensitive Electronics

Avoid spraying drive belts. Fluid Film can make them slip or wear out fast. Sensitive electrical parts need care too. While it is safe for terminals, avoid spraying exposed wires or electronic components. Lubricating these can cause malfunctions.

Correct Application Techniques

Applying Fluid Film correctly prevents common complaints and ensures lasting protection. Proper technique matters for coverage and safety. Learn how to shield sensitive parts, treat your vehicle’s undercarriage, and follow expert tips. These steps help avoid damage and increase Fluid Film’s effectiveness.

Protecting Sensitive Areas

Avoid spraying Fluid Film on brakes, exhaust parts, and drive belts. These areas can fail or slip if coated. Non-oil-resistant rubber and plastics may swell and break down. Cover or mask these parts before application. Be careful around electrical components. Use a light hand and avoid soaking exposed wires.

Step-by-step Undercarriage Treatment

Start with a clean, dry undercarriage. Shake the Fluid Film can well. Spray evenly in sweeping motions. Focus on frame rails, suspension parts, and wheel wells. Avoid heavy buildup; a thin, consistent layer works best. Let the product dry before driving. Reapply yearly or after heavy washings for ongoing protection.

Tips From Experts And Diy Videos

Experts recommend wearing gloves and eye protection. Watch DIY videos for visual guidance and real-world tips. Use extension nozzles for hard-to-reach spots. Apply in a well-ventilated area to avoid fumes. Check online forums for advice and product reviews. Practice on small areas before full application to avoid mistakes.

Credit: www.youtube.com

Fluid Film Vs Traditional Undercoating

Fluid Film and traditional undercoating serve to protect vehicle undercarriages from rust and corrosion. Both products aim to extend the lifespan of metal parts exposed to moisture and road salts. Fluid Film uses a lanolin-based formula, which differs from the wax or asphalt bases typical in traditional undercoatings. These differences affect how each product performs in real-world conditions.

Self-healing And Penetration Benefits

Fluid Film offers a self-healing property. It flows into cracks and crevices, sealing them effectively. This prevents rust from forming under the coating. Traditional undercoating tends to harden and crack over time. It does not penetrate as deeply into metal surfaces. Fluid Film’s lanolin base stays soft and flexible, allowing ongoing protection.

Durability And Abrasion Resistance

Traditional undercoating creates a tough, thick barrier. It resists abrasion from rocks and debris well. Fluid Film is softer and more oily, offering less abrasion resistance. It wears off easier under heavy mechanical stress. However, Fluid Film’s ability to remain flexible reduces cracking and flaking, which can expose metal.

Maintenance And Reapplication Needs

Fluid Film requires more frequent reapplication due to its softer nature. It can be reapplied without stripping the old layer, making upkeep easier. Traditional undercoating lasts longer but is harder to touch up. Peeling or damage to traditional coatings may require full removal and reapplication. Fluid Film’s easy maintenance suits users who prefer regular care.

Materials Compatibility

Materials compatibility is key when using Fluid Film. The product protects metal parts from rust and corrosion. Yet, it can affect some non-metal materials. Knowing which materials react helps avoid damage. This section covers paints, plastics, rubber, and electrical connections.

Apply Fluid Film carefully to keep all parts safe. Some materials need extra attention to prevent swelling, slipping, or failure.

Paints And Modern Plastics

Fluid Film is safe for most paints. It does not cause peeling or fading. Modern plastics usually resist the product well. They do not swell or degrade easily. Still, test on a small area first. Some specialty plastics may react differently. Avoid prolonged soaking of painted or plastic surfaces.

Older Rubber Compounds

Older rubber can be sensitive to Fluid Film. Non-oil-resistant rubber may swell or soften. This leads to cracks or failure. Avoid spraying bushings, hoses, and seals made from older rubber. Newer rubber compounds are usually safe. Use caution around any rubber parts that show wear or age.

Electrical Connections Safety

Fluid Film protects metal terminals from corrosion. It helps keep electrical connections clean. Avoid spraying exposed or delicate electronics. Lubrication can cause shorts or malfunctions. Use a brush or cloth for precise application. Keep fluid away from circuit boards and sensors.

Alternative Rustproofing Options

Many users express concerns about Fluid Film damaging certain parts of their vehicles. These complaints mainly focus on its effects on rubber, hoses, and sensitive components. Fortunately, several alternative rustproofing options protect these parts without harm. Exploring these options helps maintain vehicle health and prevent corrosion safely.

Non-damaging Sprays For Rubber And Hoses

Some rustproof sprays are specially made for rubber and hoses. They do not cause swelling or cracking. These sprays create a protective barrier without breaking down rubber materials. Using them keeps rubber parts flexible and durable. This option suits older rubber components sensitive to oil-based products like Fluid Film.

Electronic Cleaners For Sensitive Components

Electronic parts need careful rust protection. Certain cleaners remove dirt and corrosion without leaving oily residues. These products prevent moisture build-up and improve electrical connections. They avoid lubrication that could cause shorts or failures. Using electronic-safe cleaners extends component life and reliability in harsh conditions.

Hard Undercoatings Vs Fluid Film

Hard undercoatings form a thick, solid layer on metal surfaces. This layer blocks moisture and salt effectively. They differ from Fluid Film, which is softer and more flexible. Hard coatings resist chipping but can trap water if applied incorrectly. Fluid Film penetrates tight areas but may harm some materials. Choosing between them depends on the vehicle parts and exposure levels.

User Experiences And Reviews

User experiences and reviews offer real insight into Fluid Film’s performance. Many users share their stories online. These experiences highlight both strengths and common issues. They help new buyers understand what to expect. Below are some detailed observations from various sources.

Feedback From Automotive Forums

Automotive forums contain many Fluid Film user comments. Some users praise its rust protection and easy application. Others mention problems like sticky residue on certain parts. Several warn about spraying on rubber or brake components. These warnings come from firsthand experience. Forum members often advise testing on small areas first.

Many recommend using Fluid Film mainly for undercarriage and frame protection. Some share tips on cleaning surfaces before applying. Negative feedback usually involves misuse or ignoring product guidelines. Overall, forums provide balanced views from real vehicle owners.

Youtube Demonstrations And Tips

YouTube hosts numerous Fluid Film demonstration videos. Creators show step-by-step application processes. They highlight areas to avoid spraying, such as brakes and exhaust parts. Some videos explain how to prevent overspray on plastic and rubber. Viewers appreciate visual tips for better results.

Several videos also point out common mistakes and how to fix them. Users find these practical guides helpful before using Fluid Film themselves. Watching different channels gives a well-rounded understanding of product use and safety.

Common Mistakes To Avoid

Many complaints arise from incorrect Fluid Film use. Spraying on non-oil-resistant rubber can cause swelling and damage. Applying it on brake rotors or pads reduces braking efficiency. Avoiding exhaust system parts prevents premature product burn-off. Users should not spray drive belts as it causes slipping.

Another mistake is coating sensitive electrical connections. While terminals are safe, exposed electronics may fail if lubricated. Skipping surface cleaning before application reduces product effectiveness. Careful reading of instructions minimizes these errors. Proper use ensures better protection and fewer complaints.

Credit: www.homedepot.com

Frequently Asked Questions

What Should You Not Spray Fluid Film On?

Do not spray Fluid Film on non-oil-resistant rubber, plastics, brakes, exhaust parts, engine/transmission oil pans, drive belts, or sensitive electrical components. These areas can suffer damage, swelling, or lubricant contamination. Avoid spraying where heat or friction can degrade the product or cause slippage.

Is Fluid Film Better Than Undercoating?

Fluid Film offers long-lasting rust protection and flexibility. It penetrates better than traditional undercoating and won’t crack or peel.

How Long Does Fluid Film Last?

Fluid Film lasts from several months up to a year, depending on application and environmental conditions. Reapply as needed for best protection.

Is Fluid Film Bad For Car Paint?

Fluid Film does not harm most car paints and provides excellent rust protection. Avoid spraying on rubber, plastics, brakes, and sensitive electronics. Use carefully to prevent damage to non-oil-resistant materials.

What Surfaces Should You Avoid Spraying Fluid Film On?

Avoid non-oil-resistant rubber, brakes, exhaust parts, engine oil pans, drive belts, and sensitive electronics.

Conclusion

Fluid Film works well for rust protection when used correctly. Avoid spraying it on brakes, drive belts, and certain rubber parts. Using it on sensitive electronics or exhaust parts can cause problems. Always read product instructions before application. Proper use helps prevent damage and keeps your vehicle safe.

Understanding common complaints helps you avoid mistakes. Choose the right areas to spray for best results. Fluid Film can protect metal surfaces without harming most paints. Stay informed and apply with care for long-lasting protection.