If you’re working on your Dana 30 axle, knowing the correct torque specs is crucial to keep everything running smoothly and safely. Whether you’re replacing axle nuts, adjusting bearings, or installing new differential covers, applying the right amount of torque can prevent costly damage and ensure your Jeep or off-road vehicle performs at its best.

In this guide, you’ll find clear, easy-to-follow Dana 30 torque specifications along with important tips to help you get the job done right the first time. Keep reading to avoid common mistakes and protect your investment with confidence!

Dana 30 Basics

The Dana 30 axle is a popular choice for many off-road and light-duty vehicles. It offers a good balance between strength and weight. This axle is known for its reliability and ease of maintenance.

Understanding its key parts and common uses helps in proper care and upgrades. Knowing the correct torque specs ensures safe and efficient performance.

Key Components

The Dana 30 includes several important parts. The axle shaft carries power to the wheels. The differential allows wheels to turn at different speeds during turns.

The ring and pinion gears transfer power from the driveshaft to the axle shafts. Carrier bearings support the differential inside the housing. Seals keep dirt and water out of the axle.

Common Applications

This axle is common in many Jeep models, like the Cherokee and Wrangler. It also fits some Ford and Dodge trucks. Dana 30 is often used in light trucks and SUVs.

Many off-road vehicles use it due to its durability and availability of parts. It works well for daily driving and moderate off-roading. Many owners upgrade the axle to improve strength and torque handling.

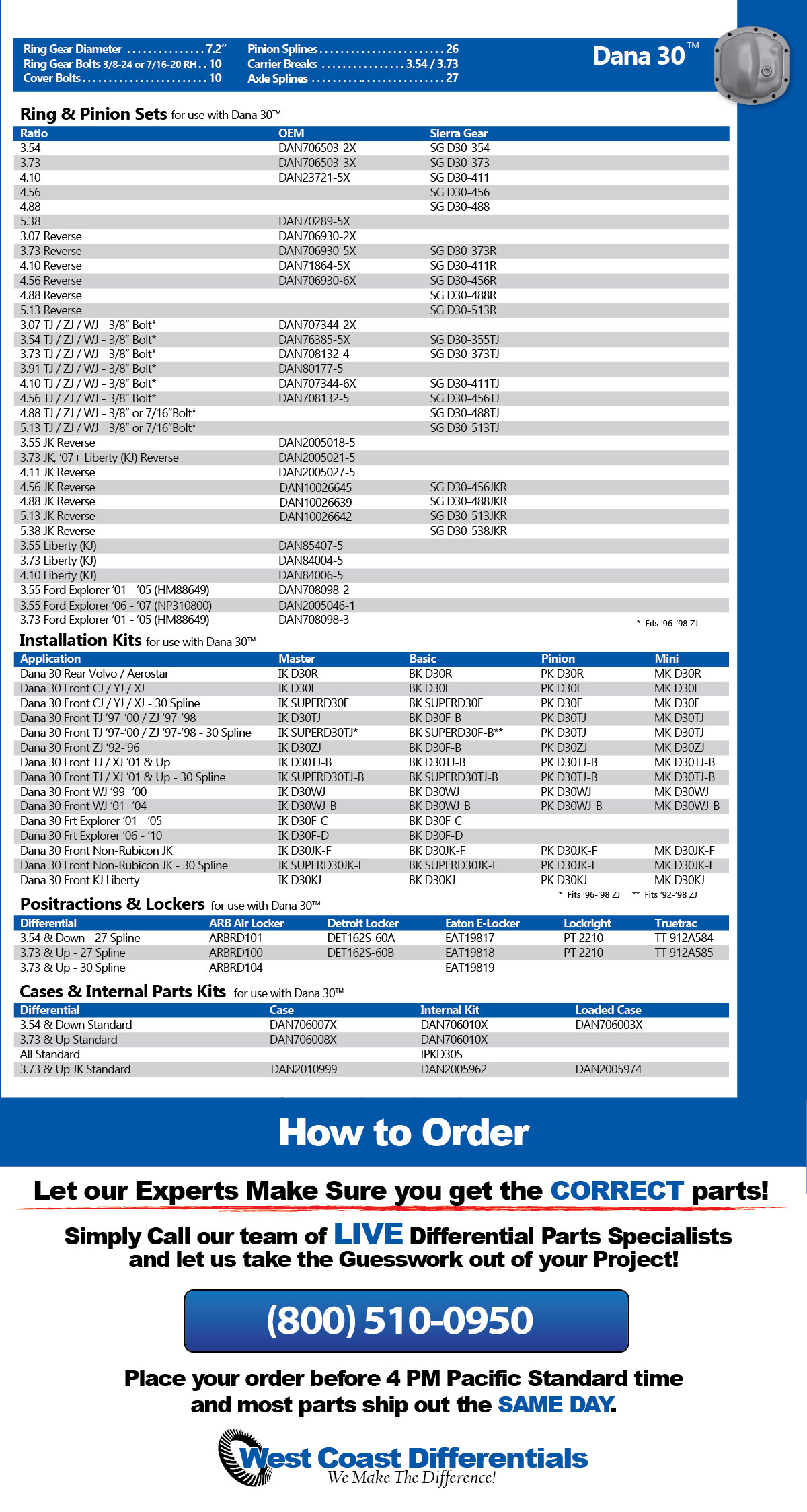

Credit: differentials.com

Torque Specifications

Tightening bolts to the correct torque is critical for Dana 30 axle durability. Proper torque prevents damage and ensures safety. Each component has specific torque requirements. Using a torque wrench helps achieve these exact values. Below are key torque specifications for the Dana 30 axle assembly.

Axle Nut Torque

The axle nut holds the wheel bearing and axle shaft in place. Tightening it too loose causes play. Too tight causes bearing damage. The recommended torque for the Dana 30 axle nut is 85 to 110 ft-lbs. Use a calibrated torque wrench for accuracy. Applying red Loctite can help secure the nut. Always re-check the torque after initial driving.

Carrier Bearing Cap Torque

The carrier bearing cap secures the differential carrier inside the housing. Tightening bolts unevenly may cause leaks or bearing misalignment. Use new bolts when reinstalling to avoid snapping. The cap bolts should be torqued to 25 ft-lbs. Tighten bolts gradually in a crisscross pattern. This ensures even pressure on the bearing and prevents damage.

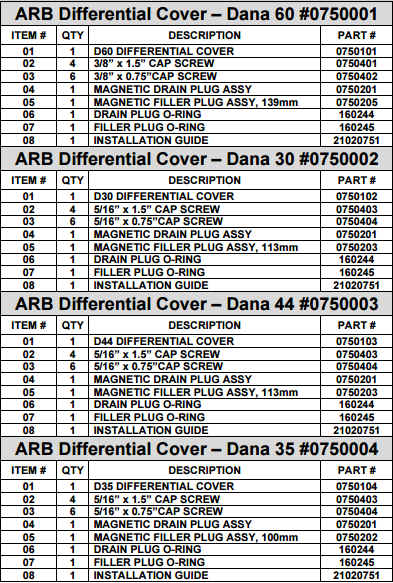

Differential Cover Torque

The differential cover protects gears and seals the housing. Proper torque avoids leaks and gasket damage. Clean mating surfaces before installation. Tighten the cover bolts to 25 ft-lbs in a crisscross pattern. Aftermarket covers might require different torque values. Always follow specific instructions for those parts. Check the gasket seating to prevent fluid leaks.

Tools For Torque Accuracy

Achieving the correct torque on Dana 30 components is essential for safety and performance. Proper tools ensure you tighten bolts to exact specifications. This prevents damage and maintains reliability. Using the right tools helps avoid over-tightening or under-tightening, which can cause failures.

Calibrated Torque Wrench

A calibrated torque wrench is vital for accuracy. It measures the exact force applied to bolts. Without calibration, readings can be off, risking damage. Always check the wrench’s calibration date before use. This tool helps maintain consistent torque, protecting parts and improving safety.

Loctite Use

Loctite can secure bolts against loosening from vibrations. Use the correct type, often red or blue, depending on the bolt’s purpose. Apply a small amount before tightening. This adds extra holding power without affecting torque readings. Avoid overusing it, which can cause difficulties during removal.

Torque Pattern Tips

Follow a proper torque pattern to distribute pressure evenly. For Dana 30, use a crisscross or star pattern. Tighten bolts gradually in stages, not all at once. This prevents warping and ensures a tight, even seal. Always clean mating surfaces before starting to improve accuracy.

Credit: www.extremeterrain.com

Assembly Tips

Proper assembly is key for the Dana 30 axle’s performance and safety. Following the right steps helps avoid damage and ensures long-lasting function. Focus on tightening bolts correctly, preparing surfaces well, and choosing the right bolts. These tips make the assembly process smoother and more reliable.

Gradual Tightening

Tighten bolts slowly in steps. Start with light pressure, then increase torque gradually. This avoids warping or uneven pressure on parts. Use a crisscross pattern to spread the force evenly. Gradual tightening helps the gasket seal properly and prevents leaks or damage.

Clean Surfaces

Remove all dirt, oil, and old gasket material from surfaces. Clean surfaces ensure a better seal and proper fit. Use a clean cloth or a mild solvent. Avoid scratching the metal to keep surfaces smooth. Cleanliness reduces leaks and makes the assembly more secure.

New Vs. Reused Bolts

Always use new bolts for critical areas like carrier bearing caps. Old bolts can weaken and snap under stress. New bolts provide the correct strength and fit. If reusing bolts, inspect them closely for damage or wear. Replace any bolts that look worn or corroded to avoid failures.

Aftermarket Considerations

Aftermarket parts for the Dana 30 axle often come with unique requirements. These variations affect torque specifications and hardware choices. Understanding these differences is vital for safe and effective installation. Always follow the specific guidelines for your aftermarket component. Below are key points to consider when working with aftermarket Dana 30 parts.

Spec Variations

Aftermarket parts may not use the same torque specs as stock components. Some are designed to handle higher stress and require tighter torque settings. Others might need looser torque to avoid damage. Check the manufacturer’s instructions carefully. Using incorrect torque can cause leaks, wear, or part failure. Always use a calibrated torque wrench for accuracy. Remember, the specs provided with aftermarket parts override stock specs.

Hardware Differences

Aftermarket kits often include different bolts, nuts, or washers. These parts may be stronger or made from different materials. Some hardware needs thread locker or special coatings. Reusing old bolts is risky since they might break under new torque. Always use the supplied hardware or recommended equivalents. Pay attention to any extra washers or spacers included. Proper hardware ensures the integrity and longevity of your Dana 30 axle setup.

Re-torque And Maintenance

Proper re-torque and maintenance of the Dana 30 axle are essential for safe and efficient vehicle operation. Over time, bolts and nuts can loosen due to vibration and heat changes. Checking and adjusting torque values helps prevent damage and ensures components stay secure. Regular maintenance extends the life of the axle and avoids costly repairs.

When To Re-torque

Re-torque the Dana 30 axle bolts after any removal or service. New installations also require a re-torque after driving a short distance, usually 50 to 100 miles. This step ensures bolts settle correctly and maintain the right tightness. Follow manufacturer guidelines for specific torque values and timing.

Checking Torque Over Time

Check torque periodically during routine maintenance. Vibrations and impacts from driving can cause bolts to loosen slowly. Use a calibrated torque wrench to verify settings match the recommended specs. Replace any worn or damaged bolts immediately. Consistent torque checks help keep your Dana 30 axle safe and functional.

Credit: www.wranglerforum.com

Frequently Asked Questions

What Is The Torque On A Dana 30 Carrier Cap Bolt?

The torque for a Dana 30 carrier cap bolt is typically 60 ft-lbs. Use a calibrated torque wrench and tighten bolts evenly in a crisscross pattern. Always replace old bolts with new ones to avoid failure. Check specific vehicle manuals for exact specifications.

What Is The Torque On A Dana 30 Differential Cover?

Torque the Dana 30 differential cover bolts to 25 ft-lbs using a crisscross pattern. Use a calibrated torque wrench.

What Is The Torque Spec For The Dana 30 Pinion Nut?

The Dana 30 pinion nut torque specification is typically 60 ft-lbs. Always use a calibrated torque wrench for accuracy.

Can You Run 35s On A Dana 30?

Running 35-inch tires on a Dana 30 axle is possible but not recommended. The Dana 30 is weaker and may fail under heavy off-road use. Upgrading to a stronger axle like a Dana 44 ensures better durability and performance with 35s.

What Is The Recommended Torque For Dana 30 Axle Nuts?

The Dana 30 axle nut torque is typically 60 ft-lbs. Always use a calibrated torque wrench.

Conclusion

Proper torque on the Dana 30 axle ensures safety and performance. Use a calibrated torque wrench for accuracy. Always tighten bolts gradually and follow the crisscross pattern. Replace old bolts with new ones to avoid failures. Check manufacturer specs, especially for aftermarket parts.

Clean surfaces and seat gaskets correctly before tightening. Re-check torque after initial use to maintain security. Following these steps protects your axle and vehicle. Stay safe and maintain your Jeep with correct torque settings.